Mobility Equipment

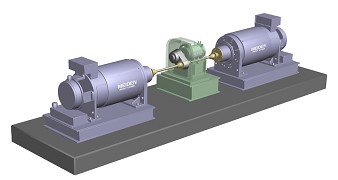

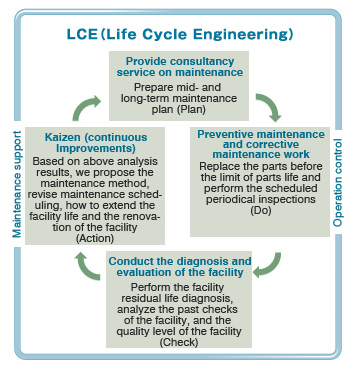

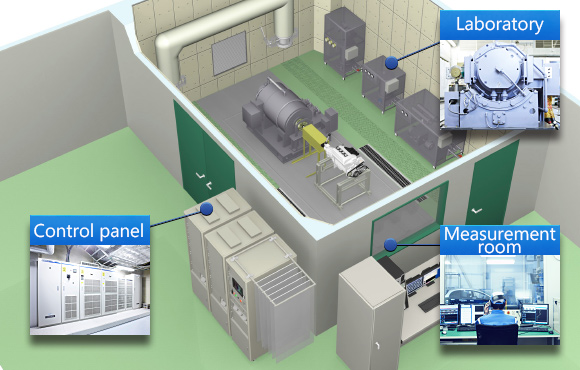

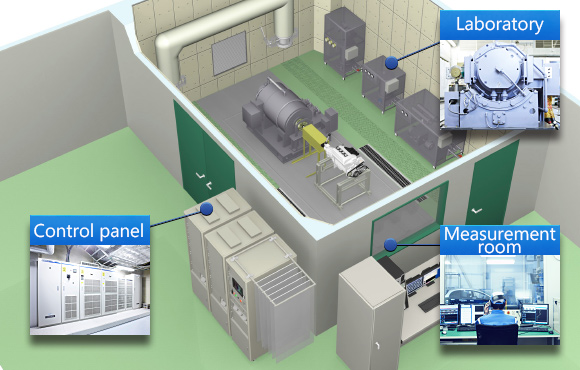

We regularly inspect, replace parts, diagnose, and update customers' equipment to constantly keep it in top condition. Together with the advance of automotive technology, dynamometer systems are required to have high functionality and high precision, and numerous types of equipment have been introduced. As a team of maintenance professionals, we provide services from the customer's perspective by means of operation control and maintenance support through consulting proposals and technical support.

Features

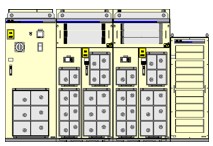

- Dynamometer systems can be broadly classified into operation and measurement (CPU) panels, control panels, and (mechanical) power meters, which require specialized knowledge to maintain stable performance. This is handled by our specialist technicians who have expertise in our equipment.

- Appropriate maintenance is performed according to the life cycle of each part.

- Maintenance preserves functionality and accuracy, and ensures that testing equipment is reliable.

Facility maintenance and inspection

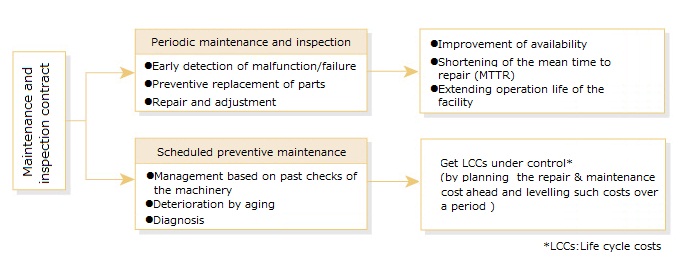

Preventive maintenance through regular maintenance

- (1)We propose the optimal maintenance and inspection cycle.

- (2)We propose replacement of deteriorated (worn) parts, etc.

- (3)We provide measurement calibration services and traceability.

Specialist engineers with expertise in the equipment conduct preventive maintenance based on accumulated data.

We also propose optimal maintenance plans that meet both the needs and budget of our customers.

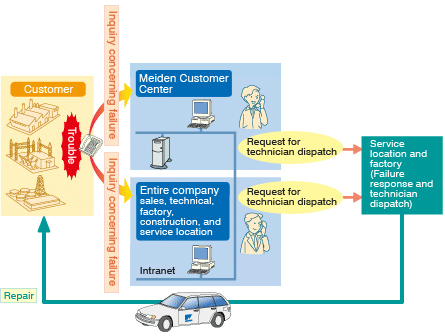

Facility repairs

Nationwide support in case of unexpected trouble

- 01We have strong cooperation with domestic service centers and production plants.

- 02We can suggest the optimal repairs based on maintenance history and risk assessments.

Please contact us about your old products and testing equipment.

- *Japan domestic only

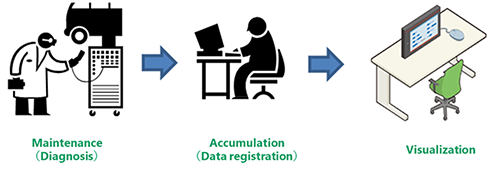

Facility management

Supporting visualization of customer facilities

- 01Management of the status of our clients' facilities using our propriety facility information management tools.

- 02Visualization of inspection cycles, inspection results, parts replacement histories, repair histories, etc.

- 03Support for preventive maintenance from visualization of facility status.