Preventive Maintenance

We propose a variety of preventive maintenance measures to keep your facilities operating in the best condition.

Inspection and maintenance

Patrol inspection*1

Abnormalities of the facilities are checked by visual inspection, meter indications and humansenses(such as vision, hearing, scent and touch.)

Simplified inspection*2

Based mainly on visual checks on external appearance of facilities, minimum checks are carried out in regard to system functions.

Regular inspection

This inspection is intended to ensure preventive maintenance by obtaining more detailed information that cannot be acquired from patrol inspection and simplified inspection.

Detailed (precise) inspection

In addition to regular inspection, equipment is overhauled for maintenance so that the equipment inside is cleaned, functions are checked, and characteristics are examined for their accuracy. In this manner, equipment is checked for its presence of abnormality.

Extra inspection

When abnormality is discovered at the time of various inspections or in the case when an accident occurs, this inspection is carried out to take restoration measures. In this case, replacement of aged parts is also carried out, as required.

- *1 Patrol inspection is performed by Meiden Engineering if the customer`s facilities can hardly be suspended.

- *2 Simplified inspection cannot be found in any general category. It is intended in order to set up a maintenance plan for regular inspection or detailed inspection.

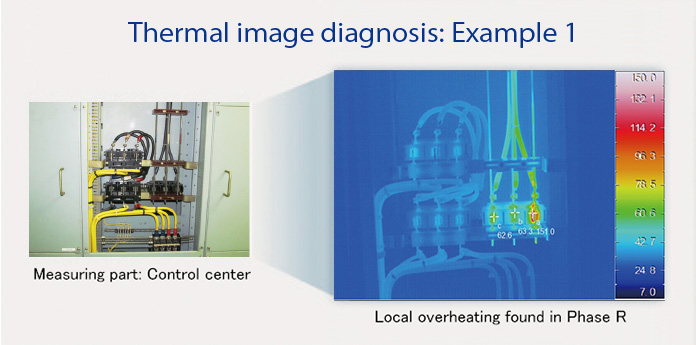

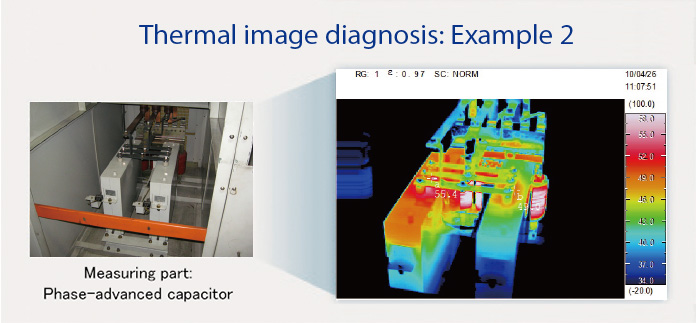

Maintenance supporting tools and facility diagnostic tools

We always use a variety of new and updated tools to accomplish qualified inspection and diagnostic services.

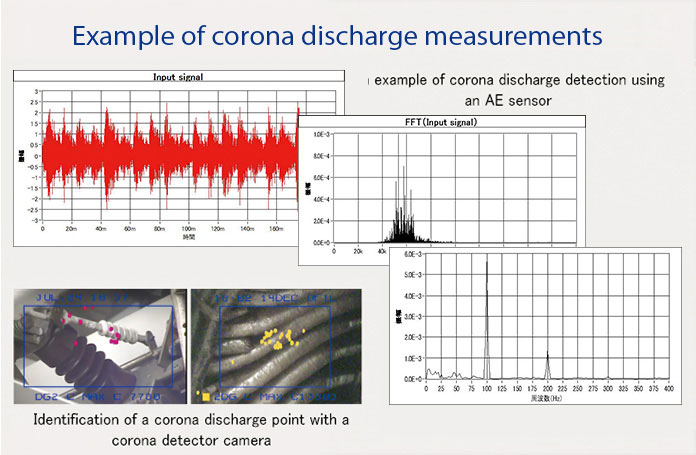

- Measurement of partial discharges

- Measurement of surface temperature

- Dielectric loss factor measurement

- Measurement of insulation resistance and contact resistance

- Measurement of noise and vibration

- Valious other measurment and analysis

- Analysis of gas in oil

Objective equipment and units for diagnosis

Using diagnostic tools, diagnostic services are given to respective equipment and units.

| Objective equipment and units | |

|---|---|

| Transformers and instrument transformers | Capacitors |

| Circuit breakers, switches, disconnecting switches | Power cables |

| GIS | Storage batteries, DC power units |

| Lightning arresters | Uninterruptible power units |

| Power fuses | Rotary machines (motors and generators) |

| Switchgears and busbar boxes | Miscellany |

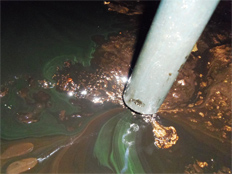

Inspection and diagnosis for subsidiary facilities of a power generating plant

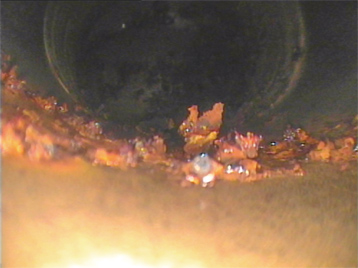

Generator sets are crucial for implementing a business continuity plan (BCP) once a disaster strikes, However, when the Great East Japan Earthquake occurred, many generators stopped working because individual fuel supply tanks became clogged with suspended sludge stirred up by vibration and the fuel could not be supplied even though sufficient fuel remained.

As measures against such earthquakes, we recommend our customers to inspect underground tanks periodically : these inspections produce remarkable results.

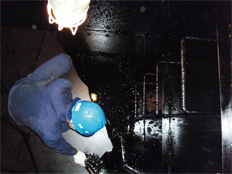

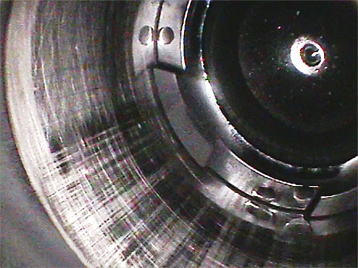

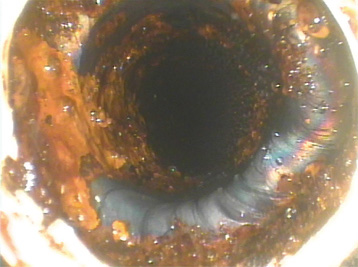

Diagnosis by industrial fiberscopes

We inspect and diagnose inaccessible and invisible parts of engines and subsidiary facilities with industrial endscope.

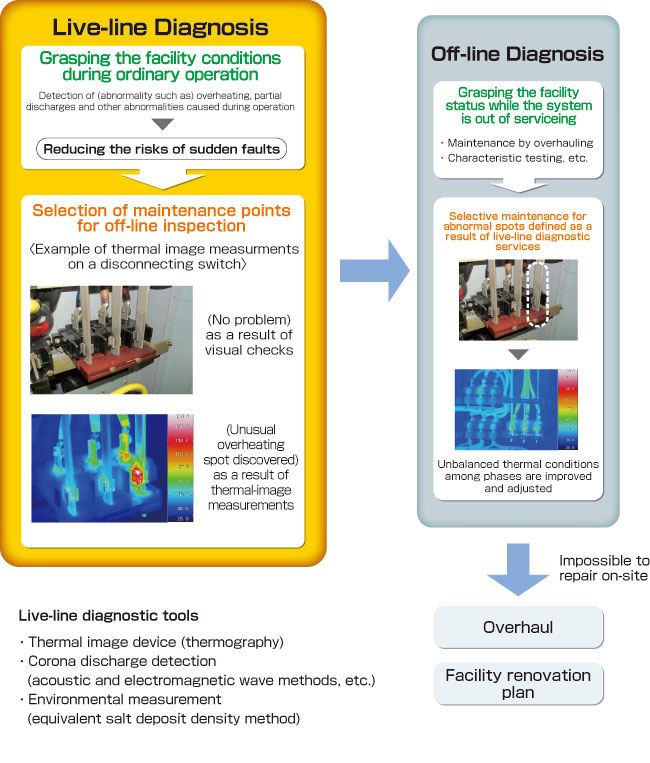

Live-line diagnosis

We propose a new preventive maintenance plan where a live-line diagnosis is added to the periodic inspection.

In order to detect a slight abnormality in advance that cannot be found by the shut-down inspection, various kinds of tools are used to support accrately this inspection.

- 01Reduces the risk probability of unexpeted accidents (grasping the early symptom of abnormality)

- 02Supports shut-down inspections efficiently and accurately (focusing on maintenance points)

- 03Effective management of maintenance cost and support of the facility renovation plan (presentation of optimal maintenance program)

Overhaul

An overhaul includes parts replacement such as bearings and brushe in rotary machines and reinsulation of windings to extend the operation life. Overhauls are performed based on the result of inspections and diagnoses.