Corrective Maintenance

We take measures quickly for unexpected accidents.

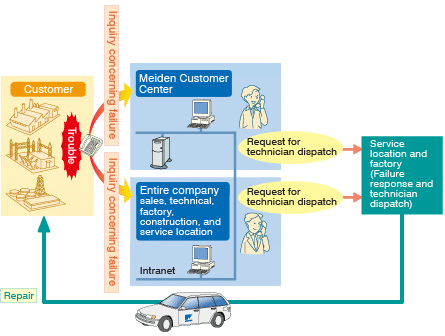

Emergency actions

Professional staff at the Customer Center are ready to accept toll-free calls from customers 24 hours a day, 7 days a week, throughout all service areas. Well experienced engineers and technicians can be dispatched from a nearby service base of the company so that customers' facilities can be recovered in the shortest amount of time possible.

- *Japan domestic only

Failure analysis

Reflection of failure analysis for preventive maintenance

- Replaced parts are examined for the cause of failure and then corrected.

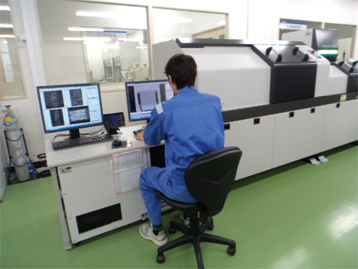

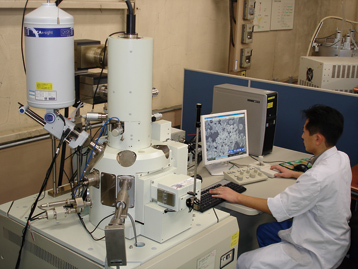

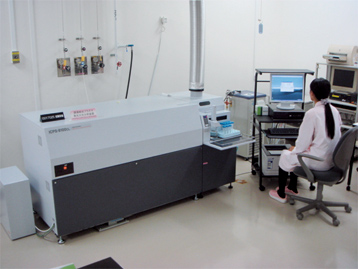

- In regard to analysis of failed parts and serious failures, we will investigate the conditions of failures and possible causes with the aid of various analytical instruments based on request from our customers. We propose our ideas of horizontal development and preventive maintenance to the customers.

Examples of failure analyzers

Inspection and Maintenance