Overall Diagnosis

The state of deterioration is grasped in order to estimate life expectancy.

Life expectancy diagnosis

Life expectancy diagnosis on an oil-filled transformer

The operational life of an oil-filled transformer is determined by the deterioration grade (mechanical strength) of insulation paper wound around the transformer coils. Progress of deterioration is greatly affected by the period of operation, machine type, and operating conditions, such as loading, oil temperature, etc. Along with progression of deterioration in the insulation paper, mechanical strength is lowered and various deterioration products (such as furfural, CO2, CO, etc.) are increased. By analyzing the amount of furfural and CO2 + CO, the grade of time-related deterioration of insulation paper can be diagnosed and the transformer life can be estimated.

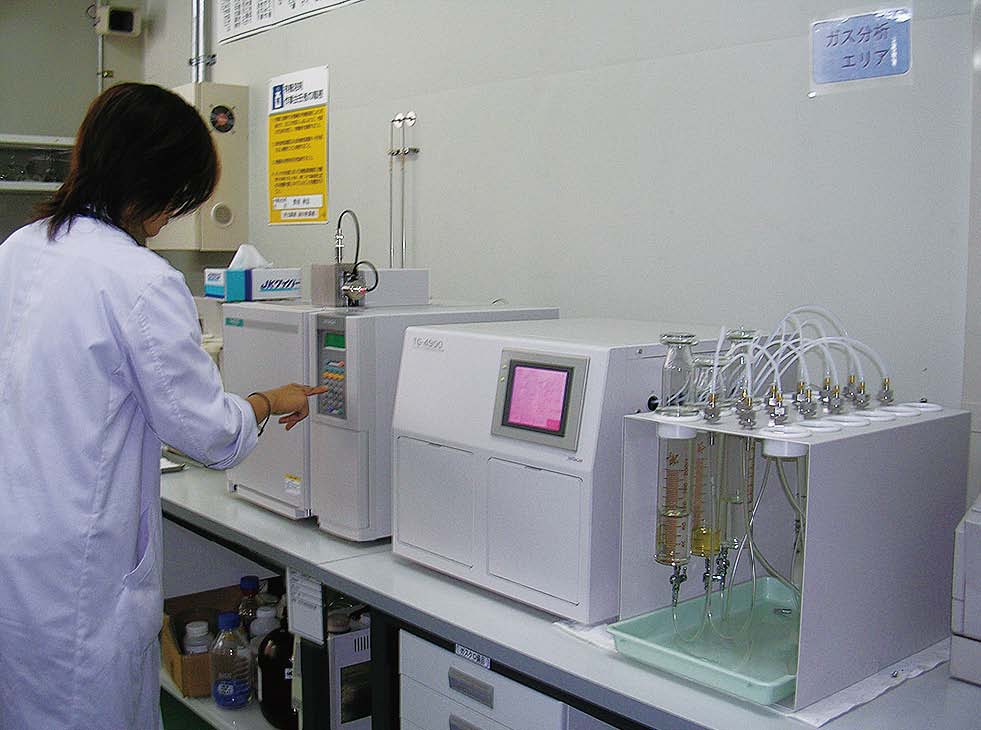

Oil analyzing techniques

For oil-filled electrical equipment, various kinds of decomposed gases are generated if there is any abnormality inside. This results in changes in characteristics of the insulation oil.

When insulation oil is sampled from equipment, gases in oil are analyzed and characteristics of insulation oil are measured. Based on the analytical result, internal conditions of equipment are estimated. This approach is helpful for early discovery of internal abnormality. In this manner, the internal conditions of equipment at the time of failure can be diagnosed.

Life expectancy diagnosis on rotating machines (motors and generators)

Advantages of rotating machine diagnosis

- Life expectancy prediction for insulation and bearings

- Necessity of overhaul and rewinding can be judged.

- The life can be aimed to improve reliabilities.

1. Insulation diagnosis

Based on the diagnostic result, estimated breakdown voltage is calculated to predict the life expectancy of rotating machines.

Process of insulation deterioration

2. Life expectancy prediction

Examples of Insulation Diagnosis Test Results for Rotating Machinery

| Type:Generator Ratings:1,250kVA-6.6kV-50Hz Measurement condition:Perform insulation diagnosis test after 21 years of delivery | |

|---|---|

| Insulation resistance: 1 minute value | 14,530[MΩ] |

| Polarization index | 6.25 |

| tanδ0 | 0.75[%] |

| Δtanδ | 0.51[%] |

| Acceleration voltage(Pi1) | 2.69[kV] |

| Current gain rate | 1.13[%] |

| Discharged capacity(Qmax) | 6,620[pC] |

| VR | 17.8[kV] |

| Dielectric strength | 44.9[%] |

| Estimated life expectancy | 3 years and 6 months |

Evaluation of stator coil life expectancy

Based on the result of Pi1 and Qmax measurement that have been acquired through the insulation diagnostic test, estimated residual insulation strength is calculated with Expression 1. According to the rated voltage and years of operation of the objective high-voltage rotary machine, predicted life expectancy is calculated from the life characteristic curve.

Expression 1: VR=E × (0.36X1-1.45X2+15.3)

VR: Estimated residual dielectric strength X1=Pi1/E

E: Rated voltage X2=Ln (Qmax)

Deterioration diagnosis of circuit breakers and contactors

We propose parts replacement or a renovation plan based on the operating conditions (number of operation times:) and the results of diagnostic tests such as contact resistance measurement.

Cable deterioration diagnosis

Judging from our diagnostic technologies and accumulated experience in regard to insulation deterioration, we propose an adequate method of deterioration factor analysis and preservation, and also offer suggestions for improvement.

- 01Evaluation of transition of current values from 1 minute to 7 minutes after a test voltage has been applied (NG in case of failure in convergence)

- 02Evaluation of the absolute value of leakage current in 7 minutes (Caution level in this case)

- 03Presence of "kick" waveform (Nil in this case)

A small amount of PCB analysis

Analysis are conducted to judge whether the equipment such as transformers and capacitors are classified as PCB waste*2. A small amount of insulation oil is sampled and a minute content of PCB is measured.

According to the Act on Special Measures Concerning PCB (Act on Special Measures Concerning Promotion of Adequate Treatment of Polychlorinated biphenyl refuses enforced in June 2001), PCBrelated waste must be disposed of or its disposal must be entrusted to a professional disposal service by March 31, 2027.

- *2 When PCB concentration in insulation oil exceeds 0.5mg/kg, it is regarded as a PCB waste.

Objective equipment requiring analysis:

Transformers, capacitors, reactors, switches, circuit breakers, etc.

Purpose of analysis:

Certificate of no contents needed at the time of product delivery, inspection at the time of abolishment.

Overall facility diagnosis

Outline of overall facility diagnosis

From the stabilized operational phase to the aging phase, we support the optimization of LCC*1 through our overall diagnostic services of facilities.

Risk analysis and development of overall evaluation

Reduction of total cost (=LCC) by introduction of CBM

Basic procedures for equipment and facility diagnosis