InvertersDirect medium voltage inverter THYFREC VT710S/P and VT730S

A direct medium voltage inverter that makes the speed of a medium-voltage electric motor variable. VT710P is a series with a power source regenerative function.

-

- Auto tuning

- Its auto tuning function makes the task-free on roublesome motor constants setting. It can make the best tuning even to the other supplier's existing motors.

-

- High efficiency operation

- During the light load operation, the motor automatically lowers the output voltage and suppressesthe no-load loss of motor. In so doing, it improves the overall energy efficiency.

-

- Operating ratio setting

- It is a computing function on the gain and bias against against the frequency setting value. It is applied when multiple motors are operated with a different speed in the production line.

-

- Frequency jump

- It can operate the motor avoiding the mechanical resonance point of the motor at the specified frequency. It is effective during the V/f control.

-

- Drooping setting

- The load can be balanced when multiple motors that are mechanically linked are operated. It becomes effective in the vector control and PM motor control modes.

-

- Simple ASR function

- Simple speed control can be performed by installing the speed detection option even when the V/f control mode is selected. High accuracy speed control is possible with simple adjustment.

-

- S-shaped cushion

- Speed changes can be made smooth to alleviate the sharp impact at acceleration and stopping.

-

- Instantaneous restarting

- Even the inverter operation stops during the power outage, its instantaneous stopping and restarting function can search the free-runninng motor rotation frequency after power recovery and match the output frequency and the voltage. In so doing, it can automatically restart the operation.

-

- DC braking

- By applying the DC power to the motor to produce the energy, braking force can be obtained by dissipating the produced energy as heat.

-

- Synchronous changeover to commercial power

- The power of the operating motor can be switched from an off-grid inverter to a grid power or from a grid power to an off-grid inverter in a shock-less manner.

Product Features

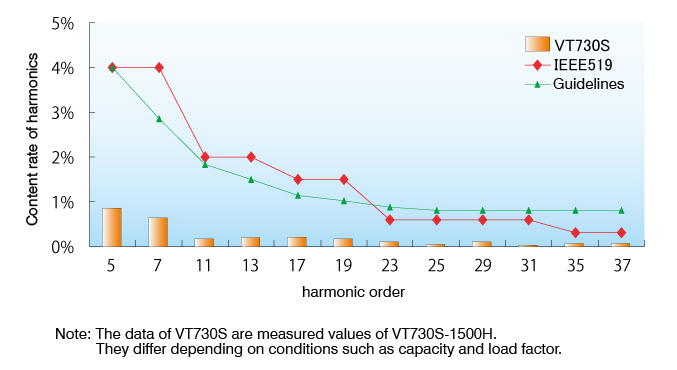

The power supply harmonic is drastically reduced by multiphase rectification while implementing a high efficiency and a high power factor. An inverter single unit meets the requirement level by the guidelines for a harmonic by Ministry of Economy, Trade and Industry in Japan.

In addition, as the surge voltage causing negative effects is suppressed by adopting an original PWM method, you can safely operate the existing installed standard motors.

By using vector control with a speed sensor (option), you can make powerful and stable operation without influenced by the load fluctuation.

- High efficiency and high power factor

- A power source regenerative function is installed (in case of VT710P).

- Reduction of the power supply harmonic

- Suppression of the surge voltage

- Powerful and smooth operation

- The standard specification is compliant with international standards: IEC and EMC directives (in case of VT730S).

- It can meet 36-phase rectification equivalent (6kV series) as standard specification (in case of VT730S).

Applications and Solutions

Fan / blower

Energy saving

By changing from the damper control for a dust collecting blower, an exhaust fan, a boiler forced draft fan, etc. to rotation control by an inverter, it can realize a substantial energy saving.

Further, by controlling the air flow by the air conditioning system or gas pressure feed system or other systems in a factory, etc. according to the time of the season or a change of factory production loads, it can realizes the energy saving.

Automation

It can make an automatic control of the air flow or the pressure on a boiler forced draft fan or a gas pressure feed system, etc. according to the operations or the demands.

Realizing a low-noise

It can realize a low-noise operation by reducing the rotation speed of motors used in a power transformer or a gas pressure feed blower, etc. installed in an urban area, etc. This control is made when the power demands decrease during the middle of the night or a certain period of the seasons.

Pump

Energy saving

By changing from the flow cotrol of the pump using a discharge valve to the rotation control by an inverter, it can produce a substantial energy saving.

By controlling the flow of an underwater pump or a cooling water pump, etc. according to the seasonal or demand changes, it can realize an energy saving.

Automation

By controlling the flow of a cooling water pump or a factory's water feed pump, etc. according to the seasonal or demand changes, it can realize an automatic control.

Conveyor

Improving efficiency and performance

It can improve the efficiency while suppressing dust generation by changing the speed according to the type of the product being carried on a conveyor. It can control the conveying amount by changing the speed of the conveyor, and also can control the compounding ratio of the raw materials by adjusting the cutting-off amount.

Automation and streamlining

It can make an automatic adjustment of conveying speed and volume according to the type of the conveying items. Further, it can make a fine-tuning of acceleration and deceleration time to prevent collapse of the conveying items.

Extruder

Automation and rationalization

It can make an automatic adjustment on extruding volume and extruding pressure level according to the type of materials.

Crane

Improving performance

It can prevent the collapse of the conveying items during the cushion start and stop. Further, the operating speed can be set up freely from a very slow speed to a high speed.

Specifications

| VT710S | VT710P (with a power source regenerative function) | VT730S (international standard compliant) | |

|---|---|---|---|

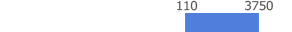

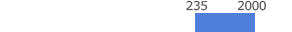

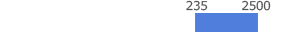

| Application motor | 110-3750kW | 235-2000kW | 235-2500kW |

| Maximum continuous rated current | 3kV series: 26 A to 400 A 6kV series: 13 A to 400 A |

3kV series: 55 A to 213 A 6kV series: 55 A to 213 A |

3kV series: 58 A to 266 A 6kV series: 39 A to 266 A |

| Overload capacity | 120% 1 min, 150% 1 min | 120% 1 min, 150% 1 min | 120% 1 min, 150% 1 min |

In case the required specification is not shown in above schedule, please feel free to contact us by the Internet inquiry form here.

power source regenerative function

Since VT710P can turn the regenerative energy generated during the motor decelerating time into the power supply. It is ideal for the application involving rapid deceleration or frequent acceleration and deceleration. It can realize a substantial energy saving by the power source regenerative function.

Control mode

- V/f (deceleration torque) control mode

- It is ideal for fan or pump application which has a square reduction torque load with a small torque in the low speed range.

- V/f (fixed torque) control mode

- The generated torque of the motor can be constant in a wide range of variable speed operation. It is applied to an extruder, a conveyor, etc.

- Vector control mode with a sensor

- It can respond to demands for high response, high accuracy, and a broad range of speed control. It is ideal for the main drive for a film line, a steel processing line, etc.

Quick reference table

This is a quick reference table showing the ranges of each series motor voltage and capacity of the motor . Just one look, you could see our offerings.

| Category | Models | voltage | Output (kw) | |

|---|---|---|---|---|

|

||||

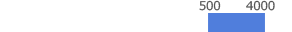

| Low voltage motor drive | THYFREC VT240S | 200V / 400V Series |  |

|

| THYFREC VT800 |  |

|||

| Related products | THYFREC CV240S | 200V / 400V Series |  |

|

| Medium voltage motor drive | THYFREC VT710S | 3000V / 6000V Series |  |

|

| THYFREC VT710P (with a regenerative function) |  |

|||

| THYFREC VT730S |  |

|||

| THYFREC CV700SB | Secondary voltage: 1570 V |  |

||

- Inquiries about this product