Facility MaintenanceMaintenance of Rotators and Electric Motors

When a sudden accident occurs, restoration of the facility takes great deal of time and incurs costs. In order to use facilities with peace of mind, it is important to perform preventive maintenance through planned maintenance. We handle deliveries, inspections, diagnoses, maintenance, repairs, and renewals in an integrated manner.

Features

- Engineers with expertise in Meidensha products provide high-quality maintenance.

- The optimal inspection cycle, parts replacement and maintenance schedule is established.

- Technicians are on standby nationwide to provide high-quality maintenance.

- We focus on the development and introduction of the latest diagnostic equipment and provide advanced diagnostic technologies.

- We have our own training facilities (Meiden Engineering Center, Manabi-ya) for engineers to pass on and improve their skills.

- Our maintenance also covers non-Meidensha rotators. Please contact us for more information.

Accident Case Studies

A case of a bearing burnout. The worst-case scenario is that this causes damage to the coils.

A case of burnout caused by accumulation of brush friction powder on the slip ring. Approximately 6 months will be needed to restore the equipment.

Maintenance and Inspection Services

We provide maintenance, inspection, and diagnostic services from the customer's perspective to ensure the long-term stable operation of facilities.

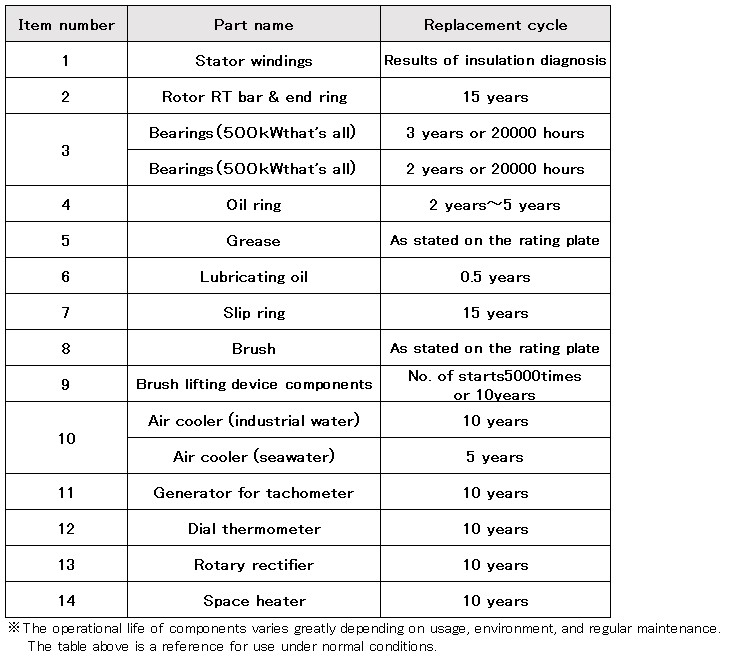

Recommended replacement cycle for major rotator parts

Rotator Diagnosis

Rotators deteriorate over time due to electrical and mechanical stresses and thermal cycles associated with operation.

Insulation diagnosis testing of high-voltage rotating machines is effective for identifying the state of coil insulation deterioration, preventing sudden coil burnout, and investigating planned overhaul schedules.

For rotators that use bearings, we conduct bearing diagnostics to determine the state of deterioration, thereby confirming the optimal time for bearing replacement.

Outer appearance of the insulation diagnosis car

Measuring devices for the insulation diagnosis

Bearing diagnosis

Introduction of Inspection and Maintenance (Rotators)

Regular inspections and maintenance are necessary to ensure safe operation.

The following are some of our rotator maintenance achievements that we have accumulated over the years. We can offer all these services.

We also have experience in many other areas. Please contact us for details.

inspection

- Visual inspection of generator interior

- The cover is removed and the interior visually inspected.

In the case of a detailed inspection, a fiberscope inspection is also used.

- Open inspection of bearing metal

- A precision inspection when metal is used for the bearing involves an open inspection of the metal.

- Bearing metal collar check

- In the case of conducting an open bearing inspection, the bearing metal collar is checked.

- Air cooler cleaning

- A detailed inspection of the air cooler is performed by cleaning the inside of the element and conducting a water pressure resistance test.

- Carbon brush inspection

- An inspection of a wound-rotor induction motor focuses on the inspection and cleaning of the current collection part.(The photo shows an inspection of the carbon brush sliding surface)

Maintenance

- On-site bearing replacement

- Bearing maintenance conducted by replacement with new parts.

Bearing replacement can be performed on site.

- Factory steam cleaning treatment

- When an overhaul is performed, the instrument is brought to the factory, cleaned, dried, and varnished, and parts are replaced and tested.

(The photo shows steam cleaning in progress.)

Technical support service information

Click here for the details of the maintenance services and locations of Meiden Group.

- Inquiries about this product