ICTCloud service for facility maintenance

“Meidensha’s smart maintenance system with IoT effectively utilized enables maintenance to be performed according to equipment conditions instead of conventional periodic maintenance based on the number of months and years, allowing a shift from TBM (Time Based Maintenance) to CBM (Condition Based Maintenance). IoT technology allows efficient performance of such work as inspection, repair, and renewal that are indispensable for continuous and safe use of electrical equipment, proactively preventing failures and other troubles of equipment and reducing maintenance management costs."

Features

- Efficiently gather equipment information by making use of know-how accumulated through a vast track record in maintenance.

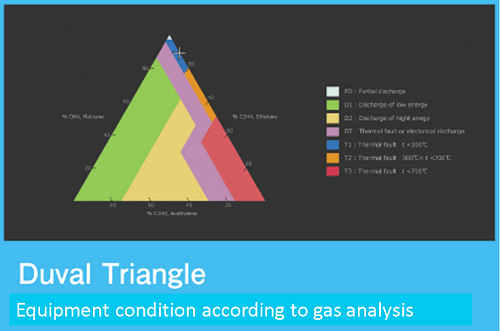

- Provide equipment diagnosis on the cloud by analysis technologies that merge measurement data and knowledge of devices.

- Propose optimum lifecycle for electrical equipment based on the diagnosis results.

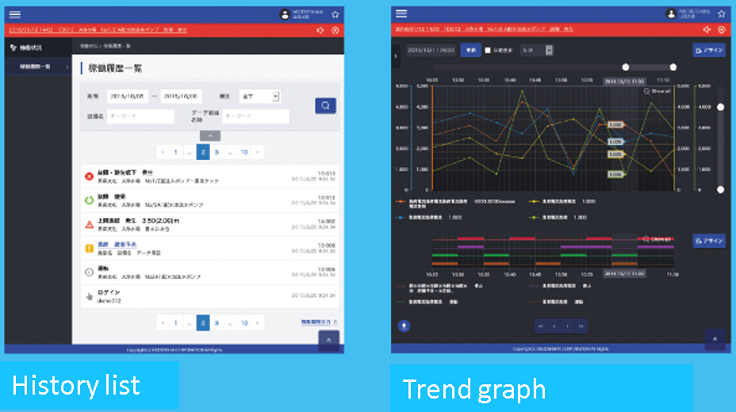

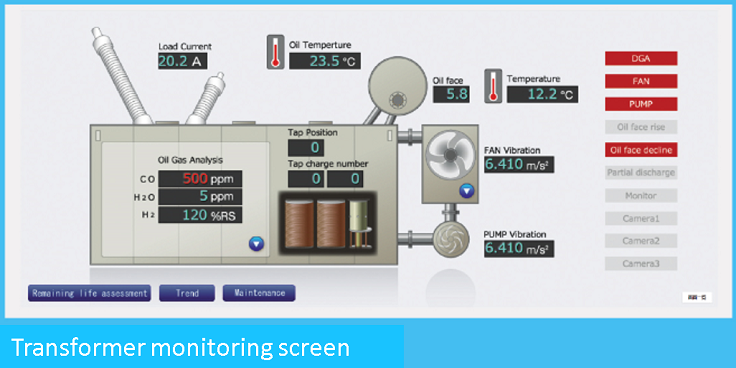

Remote monitoring/Data measurement

- Adopting a cloud-based system reduces initial costs and eliminates the need for server administration.

- Equipment condition can be viewed at anytime and anyplace via the cloud.

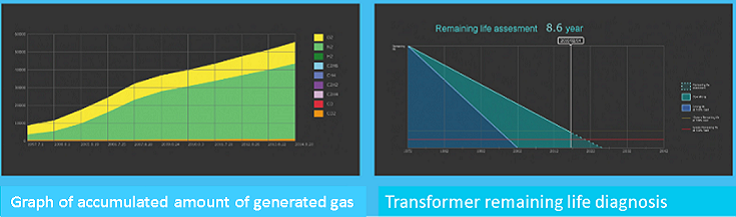

- Showing a failure history list and graphed measurement data allows simple analysis and diagnosis.

- Vibration, sound, current and other waveform data are gathered in real time.

- A failure is notified in real time by e-mail.

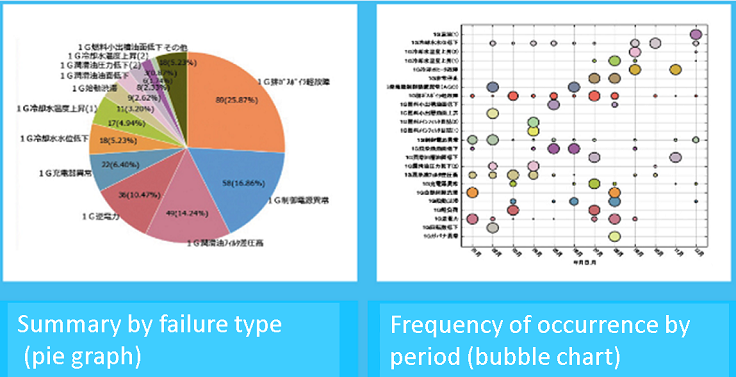

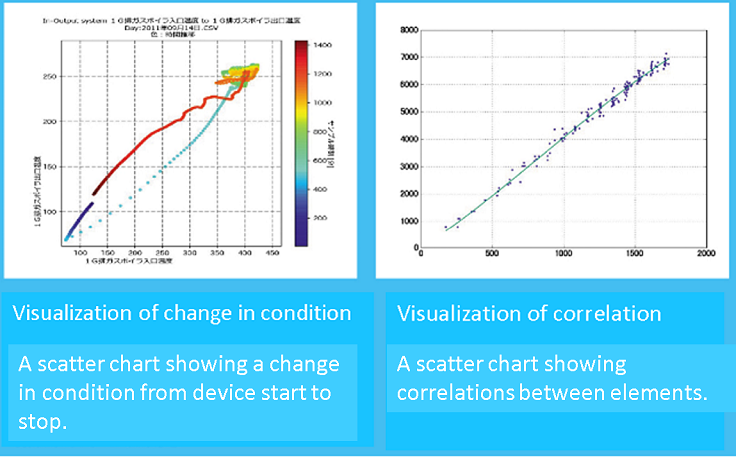

Visualization of data

- Perform a high-level analysis of large volumes of gathered data such as equipment operation status and measurement results accumulated using existing monitoring and control systems, and visualize trends in equipment failures and frequency of their occurrence.

- AI analyses the visualized analysis data for possible signs of failure.

Equipment diagnosis

- Automatically diagnose equipment remaining life with high precision based on analysis results.

Lifecycle cost optimization

- High-precision diagnosis allows efficient equipment planning, reducing maintenance costs.

- Accurate equipment condition monitoring allows maintenance to be performed on selected items at the optimum timing instead of conventional periodic maintenance.