Semiconductor manufacturing equipmentPure Ozone Generator (High-concentration Ozone Gas Generator)

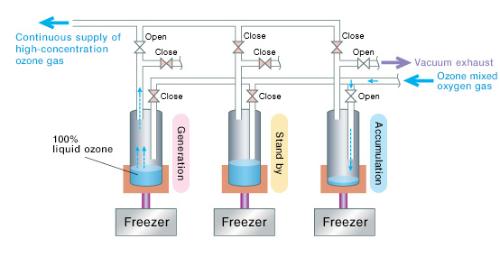

It is an unit that can safely and continuously produce ozone gas at the concentration level of nearly 100%.

Product Features

Meiden Pure Ozone Generator is a unit that liquefies and stores the ozone gas and supplies high-purity ozone gas continuously. Because of high purity ozone level, it can be used as an oxygen radical generation source for a semiconductor process. For safety, the unit has sufficient safety measures.

Furthermore, this unit was jointly developed with the National Institute of Advanced Industrial Science and Technology in Japan.

- Explosion-proof design for emergencies

- During the power outage or abnormal situation, it can control temperature and pressure by a fail safe system.

- Compliant with international safety standards SEMI-S2, UL, NFPA, CE, etc.

- For safety level against gas leak it was proven by a tracer gas test by a third party cerfifying body.

Applications and Solutions

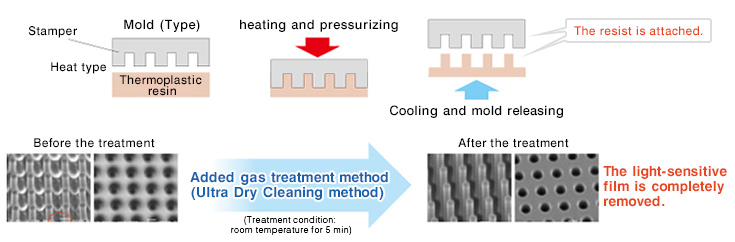

Removal of a stamper in nanoimprint (use of the added gas treatment method)

- Complete removal of the resist attached to the stamper

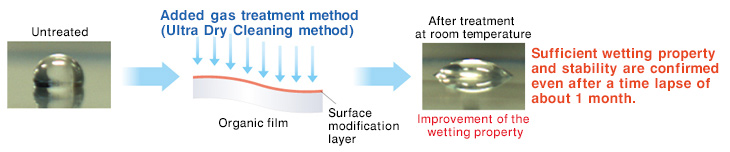

Surface modification of the film (use of the added gas treatment method)

- Improvement of the wetting property by the surface modification of the film

Specifications

For specifications and outline drawing, see the catalog.

Applicable fields

| Field | Category | Applicable technology | Expectation effect |

|---|---|---|---|

| Environment | Water treatment | Pure ozone treatment method | Disinfection, deodorization, and decolorization |

| Medical treatment | Medical equipment | Pure ozone treatment method | Sterilization and pharmaceutical (organic synthesis) |

| Film | FPD related | Added gas treatment method | Surface modification and coating of film for touch panels, etc. |

| Semiconductor mounting related | Surface modification and coating of film for FPC, etc. | ||

| Food related | Surface modification of packing material | ||

| Battery related | Surface modification of film for solar cells, etc. | ||

| Materials | Member | Pure ozone treatment method | Carbon nanotube modification and spherical silicon oxidation |

| Battery | Electrodes | Added gas treatment method | Electrode member modification |

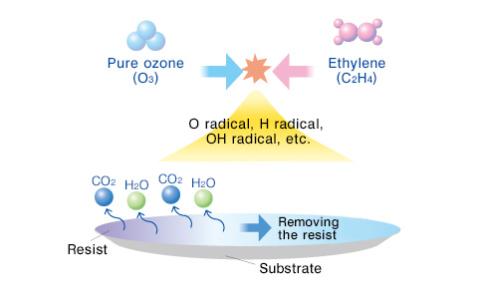

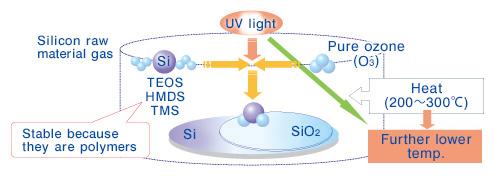

| Semiconductor | Film forming process | •Pure ozone treatment method •UV ozone CVD process method •Added gas treatment method |

Oxidation, CVD, insulating film modification, ashing, and dry cleaning |

| Lithography | Photomask modification, precision part cleaning, and EUVL | ||

| Advanced system | MEMS | •Pure ozone treatment method •Added gas treatment method |

Ashing and dry cleaning |

| Nanoimprint | Dry cleaning of stampers | ||

| Micromachining related | High temperature superconductor film and molecular beam epitaxy (MBE) | ||

| Printed electronics | Surface modification and coating before and after the printing step |

- Inquiries about this product