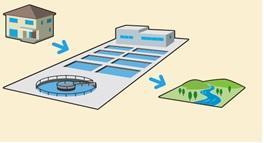

Facility MaintenanceMaintenance of water treatment plant facilities

Water treatment facilities (such as the water purification plants and water reclamation centers in various regions) consist of power receiving and transforming facilities, monitoring and control equipment, and instrumentation equipment, therefore requiring extensive knowledge. We work closely with our customers in order to resolve their issues, and help to ensure smooth operation of their facilities through periodic inspections and emergency maintenance.

Features

- Water treatment plant facilities are in constant operation, 24 hours a day, 365 days a year, and a sudden equipment failure can affect people's lives. Our technicians can take responsibility for responding to such issues.

- Facilities are operated in a variety of ways. We propose maintenance methods that minimize impact through appropriate timing in line with time slots where stoppage is possible.

- We properly ascertain when to renew equipment. We propose life-extension measures for equipment and partial renovations (selection of retrofit equipment) to match old equipment.

Malfunction Case Study (Control Center Burnout)

Some water treatment facilities are frequently cycled between operating and stoppage, leading to the equipment deteriorating significantly.

Failure to perform periodic inspections and maintenance may result in heat generation and burnout of the equipment.

Cleaning and tightness checks inside the unit and periodic replacement of the electromagnetic contactor and guard relay are necessary.

C/C unit burnout

Burnt out section

Technical support service information

We undertake maintenance and inspection work on behalf of our customers for the long-term stable operation of their facilities.

monitoring equipment

Inspection of monitoring equipment

Inspection of monitoring equipment [controller PLC / sequencer SQC]

Normal (simple) inspection (inspection while equipment is in operation)

1.Program operation status check

2.Creation of backup program

3.Error history check

4.Appearance check

5.Cleaning

before update(ADC4000)

Precise (detailed) inspection (inspection while equipment is stopped)

1.Program operation status check

2.Creation of backup program

3.Error history check

4.Appearance check

5.Cleaning

6.PC board cleaning

7.PC board input/output all-point function check

After update(ADC6000)

The following suggestions are made based on the inspection results.

(1)Proposals for improvement of defective parts

(2)Creation of maintenance plans

(Information on parts to be periodically replaced until equipment renewal)

(3)Proposal of renovation plan

【Meidensha PLC compatible models】

ADC6000、ADC5000、ADC4000

ADC600、RC500、RC200、RC100

VC5000、VC100(New JIS-compliant model)

※We have experience in replacing obsolete models

Switchgear Equipment

Protection relay test

Inspection of switchgear

Inspection details

1.Appearance check

2.Protective relay test

3.Insulation resistance measurement

4.Accuracy check and adjustment

5.Protective interlocking test

The following suggestions are made based on the inspection results.

(1)Proposals for improvement of defective parts

(2)Creation of maintenance plans

(Information on parts to be periodically replaced until equipment renewal)

(3)Proposal of renovation plan

【Target models】

High-voltage panels, low-voltage panels, control centers,

auxiliary relay panels, etc.

Instrumentation Equipment

Transmitter adjustment

Inspection of instrumentation equipment

Inspection details

1.Appearance check

2.Function tests

3.Accuracy check and adjustment

4.Settings data checks

Inspection of general instruments

The following suggestions are made based on the inspection results.

(1)Proposals for improvement of defective parts

(2)Creation of maintenance plans

(Information on parts to be periodically replaced until equipment renewal)

(3)Proposal of renovation plan

【Target models】

1.Measuring instruments - flow meters, pressure gauges, water level gauges, etc.

2.Transducers - isolators, alarm set stations, integrators, etc.

3.Water quality meters - residual chlorine meters, DO meters, MLSS meters, turbidity meters, etc.

Technician Training

During training

Our Manabi-ya training facility opened in October 2020. This facility provides training automatic control by storing water in two water tanks and using pumps to control supply and return of water. Using this water treatment plant training equipment, we are working to develop engineer human resources at an early stage by providing them with practical training in an environment that is the same as customers’ facilities.

- Enquiries about this product

-

- [Department Line: 1]