ProjectsIndustrial plant – Kina Seguntor Biomass

Introduction;

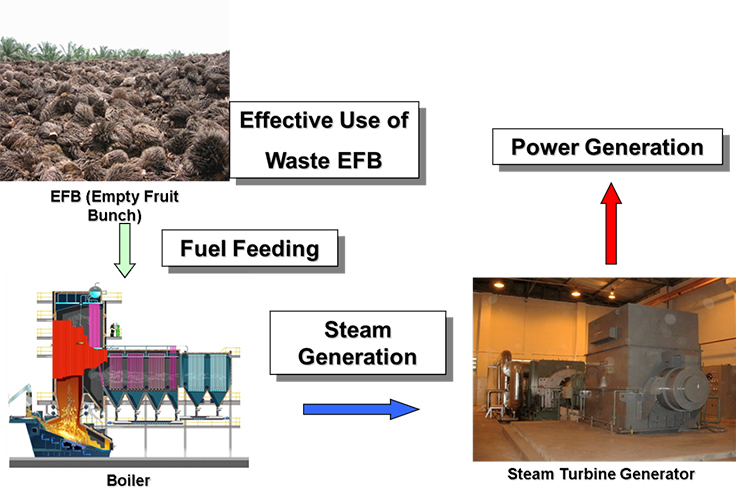

The CDM(Clean Development Mechanism) was booming in world wide after the authentication of COP3(Kyoto Protocol) in 1997. Meidensha has entered to the big challenge of new technology of Biomas Plant adopting the abundant empty fruit bunch (EFB) from palm oil mills in Malaysia having the large potential of renewable energy resource that could meet the energy demands in Malaysia. This is also in line with the vision and direction of Malaysia in enhancing renewable energy and reducing dependence on fossil fuels for its energy needs.

2 location of Biomass Plant at Kina and Seguntor have been implemented with the identical design and major system supported with Vyncke (Bergium) for Boiler System , Jebsen & Jessen (Brasil) for Turbin System. The Fuel handling system, overall mechanical electrical system have been managed by Meidensha.

The Fuel handling system is one of the big challenge of Meidensha , design manufactured and built. Pre-treatment steps for the EFB such as shredding/chipping and dewatering (screw pressing or drying) are key factor improving the fuel properties of the EFB before it is sent for combustion to power electricity generation. Various assessments of cost effectiveness in terms of logistics, treatment process and Fuel quality has been studied and It was decided to build and operate the Fuel Handling System aside the Power Plant.

The plant is continuously running to date and contributing the base power supply in Saba area.

Operation Cycle and Strategy

Specification

| Description | Specification |

|---|---|

| Fuel Consumption (Designed Value) | 23.123 kg/h (Pressed EFB) |

| Installed Capacity | 11.4 MWe gross / 10.0 MWe net |

| Boiler Capacity | 56 t/h 43barA 420degC |

| Emission Standard (Designed Value - 25degC 1atm dry basis) | <400 mg/m3 (Particulate), <400 ppm (SO2), <400 ppm (NO2) |

| Cooling Tower | Mechanical Draught Cooling Tower, Counter Flow, Water Flow : 2,491 t/h, Wet Bulb : 28 degC, Hot Water Temp : 42 degC, Cold Water Temp : 32 degC |

| Generator | Totally Enclosed Water-air Cooled, Three Phase Four Pole, Synchronous Generator, 13,059 kVA x 4P x 6,600 V x 50 Hz x 1,500min-1 x 1,142A |

| Step-up Transformer | ONAN : 8,000 / 10,700 kVA x 3Ph x YNd11 x (6,600 – 22,000/12,701 V) |