Automotive Test SystemsTest solution

We have R & D laboratories in both Japan and the U.S. (for North America) to verify and evaluate our dynamometer systems products. In so doing, we make our testing systems meeting the needs of the customers. Over there, we perform the contract testing service, joint development, renting of the test system with the customers.

Features

- High level testing system necessary for automotive development

- Our sufficient expert engineers will work on the various testing.

- Our testing services cover a broad range: from individual components such as engines and transmissions through the complete vehicles

- The customer can check the evaluation before the system introduction planning.

Dynamometer System R & D Laboratory

- Total floor space:

- 1,396 m2 two story building

- Design & Construction :

- Meidensha Corporation and Meiden Plant Systems Corporation

- Main equipment:

- Engine Benches

- Chassis dynamometer

- Anecoic Test Room

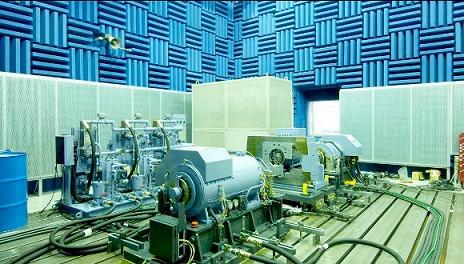

Anecoic Test Room

10 m x 10 m open space for anecoic tests and tests of drivetrain components

- Background noise level: NC20 (sound absorbing material: wedge shape urethan form)

- 10 t crane

- Lowest cut-off frequency: 350 Hz

- Modal analysis device: I-DEAS Modal Lite

- Base plate 7 m x 7 m base plate with slits

- Acoustic measuring system : B&K PLUSE

- The engine operable is possible in the Anecoic Test Room (Fully equipped with an exhaust gas trigger facility, a fuel supply facility, and a cooling water facility)

Chassis Dynamometer Test Room

LDV-4WD CHDY

- Roller over-hang type dynamometer

- Controller MEIDACS-6200P

- Exhaust gas analyzer

- Driving robot

Engine test room

Virtual engine test bench (steady and transient state test bench)

- Virtual controller

- Liquid cooled dynamometer 300 kW

- Exhaust gas analyzer

- Air conditioner for intake air temperature control

- 吸入空気流量計

- Enquiries about this product

-

- [Extension No.3803]