Railway systemOverhead Catenary Inspection System for Railway (for KERETAPI TANAH MELAYU BERHAD)

- Merits of introducing our product(s)

-

Thanks to the latest Image processing technology and composite data integration, Catenary Eye provides the high speed and accurate data aquisition and realize the visualized image check of the Catenary condition prior to mobilize the maintenance team to site. It will remarkably save time and cost of maintenance.

In the event of KTMB maintenance strategy, the current manal inspection of 2km per day could be expexted to speed up to maximum of 480km.

Background

The 1st Catenary Eye in Malaysia has been supplied as a part of Offset Program leveraging from the procurement of KVMRT Project, which managed by Technology Depository Agency (TDA) and benefitted to KTMB in terms of knowledge transfer and exposure to new technology on railway industry maintenance. The system is Catenary Eye Class 4 , which was mounted onto existing dedicated maintenance vehicle.

Since the high performance of Catenary Eye has been appreciated, the additional 6 sets of the same are planned to be implemented for KTMB to enhance the high quality maintenance and operation traveling down through Peninsula Malaysia for 1,000km.

KTMB Catenary Eye

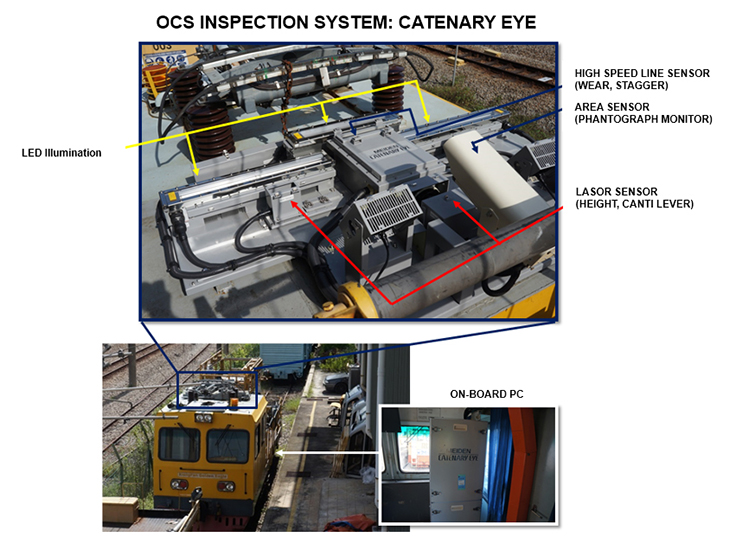

KTMB Catenary Eye Class 4 mainly consist of ;-

【ROOF TOP】

2-sets of High Speed Line Sensor for Wear and Stagger

1-set of Area Sensor for Pantograph Monitor

2-sets of Laser Sensor for detecting of cantilever structure

3-set of LED Illumination at Front, Right and Left

1-set of Laser Range Scanner for Height

【INTERIOR】

1-complete set of On-Board Computer System

1-set of Display for Pantograph Monitor

【UNDERCARRIAGE】

1-set of Doppler Sensor for Speed Detection

【WAYSIDE – OFFICE】

1-complete set of Off Line Computer and Printer