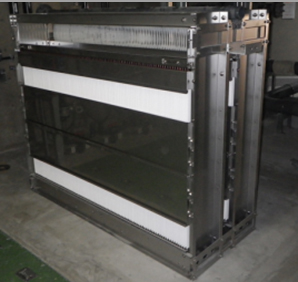

Ceramic flatsheet membrane systemHotel Grand Pacific LE DAIBA Kitchen Wastewater Reuse

- Merits of introducing our product(s)

-

We realized both environmental management and cost reduction at the same time.

Better processed water quality by the membrane bioreactor (MBR) system.

Reuse of the processed water as washing water for toilet

Reduction of operation costs at water and sewage treatment plants

Background of Introduction

he key points in adopting ceramic membrane bioreactor (MBR) using our ceramic flatsheet membrane units are: it can be applied to kitchen wastewater and miscellaneous wastewater as they are oily and with impurities (fibers and hairs); easy maintenance by automatic cleaning control; and as the ceramic membrane unit being compact, its installation to the underground facilities with the limitation of the height above the floor and the depth of the water tank are limited.

Outline of the facility

Commercial operation since 2014

Treatment flow: Biological treatment + MBR → Ozone treatment

Raw water: Kitchen wastewater and miscellaneous wastewater

Throughput: 300 m3/day

Reuse of wastewater: Washing water for toilet