Common Fundamental Technologies

This page describes the common fundamental technologies underpinning the reliability of Meidensha’s core products. Common fundamental technologies are overseen by our Analysis Center, Quality Assessment Center and High Power Lab. The Analysis Center provides analysis and CAE to assist design work. The Quality Assessment Center uses a number of different analysis technologies to help improve product quality and prevent defects. The High Power Lab provides performance check testing for heavy electrical products. The page below provides a brief description of each facility.

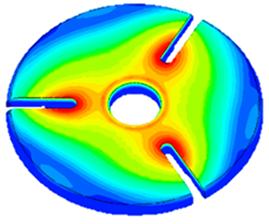

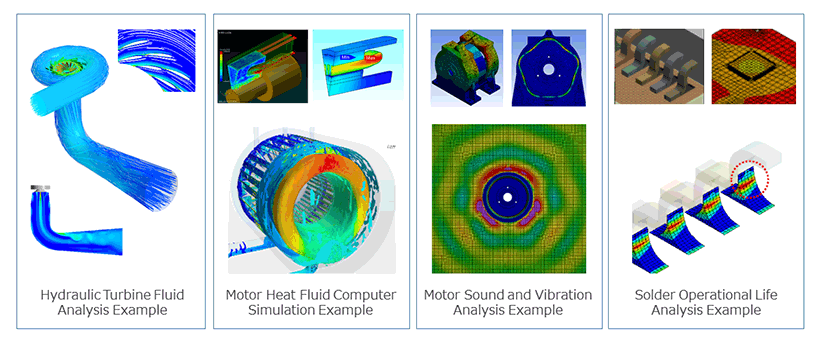

Helping improve product quality by using CAE to validate designs and investigate defect causes

A wide range of Meidensha Corporation product areas are assisted by computer simulation technology (CAE technology). It is used to boost hydraulic turbine efficiency, create thermal designs for motors, and analyze the operational life of the solder used in electronic circuit components.Using a calculation server for large-scale and high-speed analysis helps improve product quality.

Creating more advanced CAE technology through R&D, ensuring product quality through Companywide CAE use

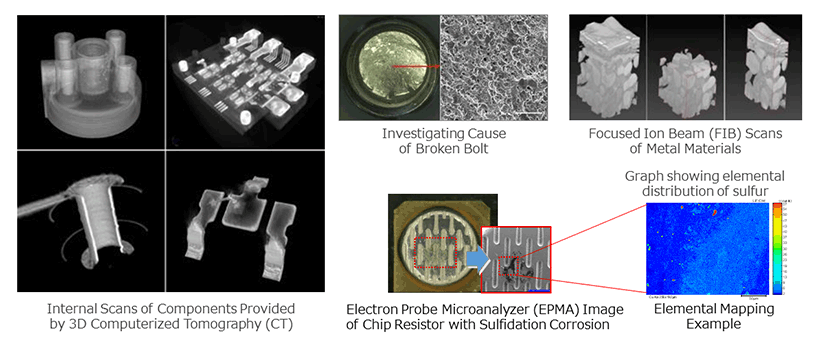

Using several types of equipment analysis to help improve product quality and prevent defects

In addition to quality evaluations and reliability testing for materials and parts used in products, analysis technologies are used to help investigate the causes of product defects if they occur and provide solutions.

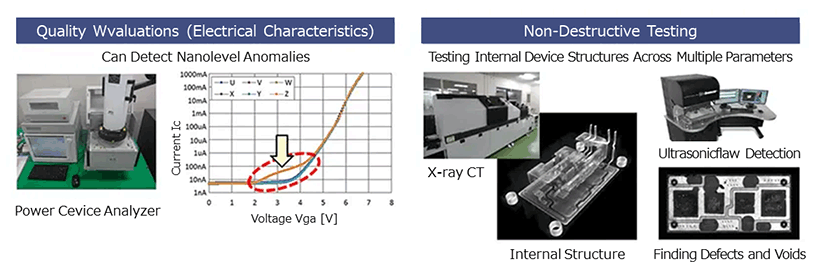

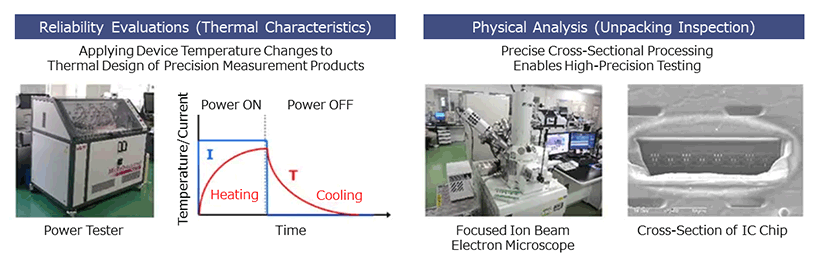

Technology for evaluating semiconductor devices used in power electronics products

Providing high quality and reliability through detailed analysis and evaluation

Meidensha uses a combination of non-destructive testing and physical analysis to evaluate and analyze the internal structure and characteristics of semiconductor devices used in products. Product reliability is ensured by using evaluation methods optimized to each device type and standard.

- Using Meidensha’s own inventive evaluation and analysis technologies to ensure the reliability of purchased semiconductor components

- Creating standard-compliant evaluation methods optimized to different types of devices

- Detailed evaluations combining non-destructive testing and physical analysis

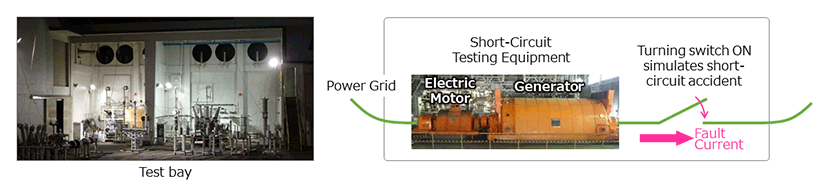

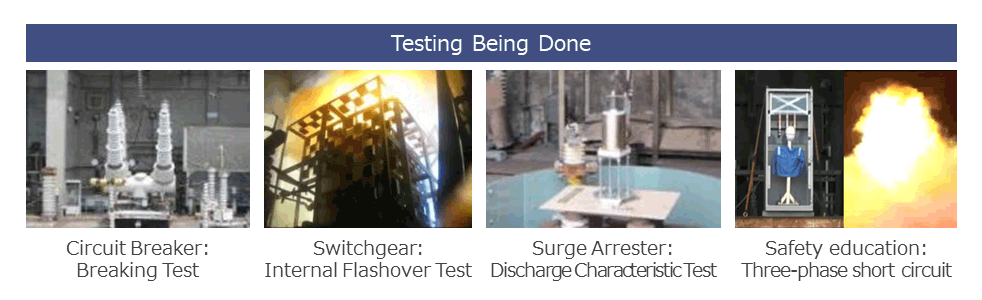

Simulating short circuits and other grid accidents, checking whether equipment works as specified

ISO 17025 accredited (test certificate available upon request)

Primary testing types

Breaking performance and current resistance performance of currents during short-circuits (accidents), internal condition monitoring during flashovers, safety education, other

Applicable devices

Switchgear, circuit breakers, surge arresters, transformers