Intelligent Information Technologies

Meidensha is developing intelligent information technology as a way to apply AI (artificial intelligence) to our business areas. AI creates new value by learning from various observations made about equipment, serving as a substitute for human workers. This page presents AI technology created to address the issue of dwindling populations, drive robot control technology providing accurate vehicle road test simulations, and image recognition-based monitoring technology for rail line equipment. This page presents AI technology created to address the issue of dwindling populations, drive robot control technology providing accurate vehicle road test simulations, and image recognition-based monitoring technology for rail line equipment.

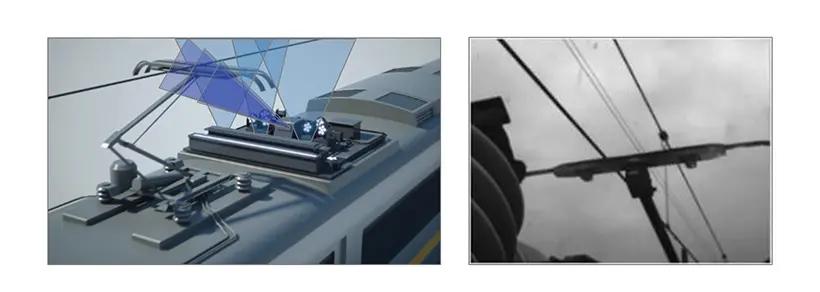

Diagnostic systems for rail line equipment (image-based diagnostic systems)

Catenary Eye (camera image-based analysis system)

- Measures contact wire height, deviation, wear, hard spots and contact force

- Detects rail line equipment problems

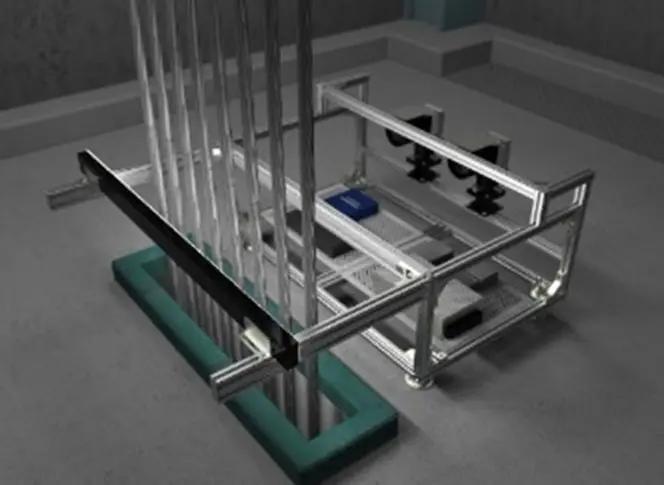

Elevator rope testers (image-based diagnostic systems)

Use image-based analysis technology to inspect elevator rope condition

Apply rolling stock line equipment diagnostic system technology

- Enable measurement during high-speed elevator travel

- Measure parameters such as narrowing and deformation over entire rope length in a single operation

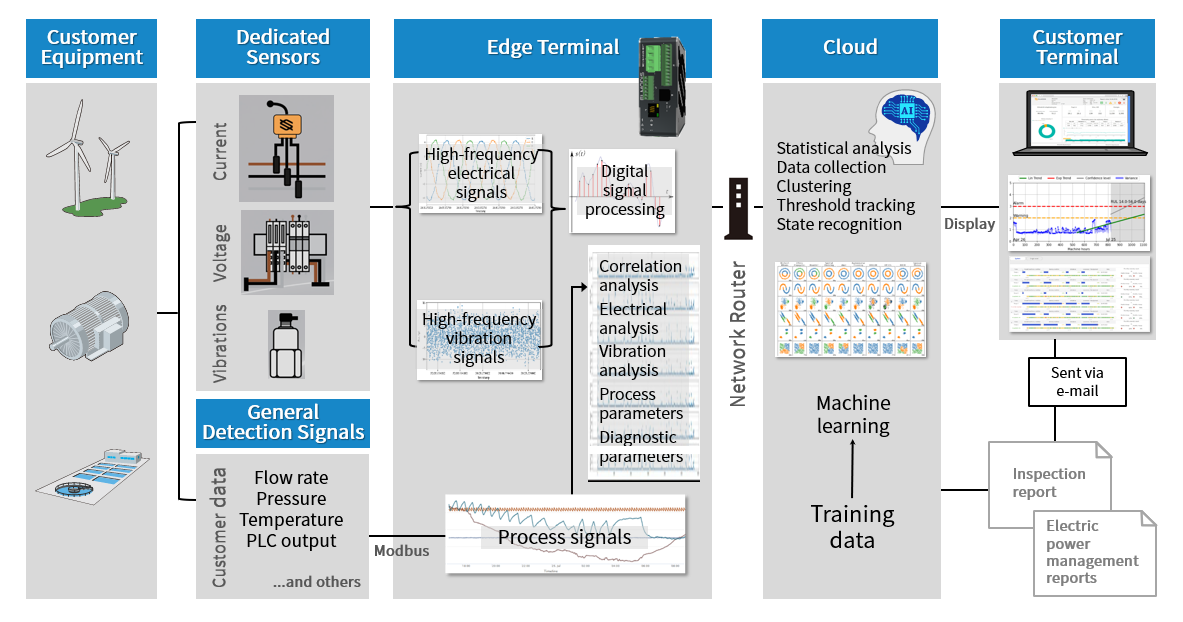

Rotator equipment diagnostic system (AI diagnostics)

REMOTIER (rotator remote monitoring and diagnostics)

- Optimized machine-learning models selected based on equipment type

- Multidimensional correlation analysis for three-phase currents, voltage signals, vibration signals, and various other process signals

- Includes equipment soundness monitoring, operating efficiency visualization, and energy management functions

Driving robot

Simulated vehicle road performance testing

Deep reinforcement learning

<Inputs>Engine speeds, speed commands, other

<Outputs>Estimated accelerator and brake operation levels

Highly accurate vehicle performance assessment testing (for driving modes)

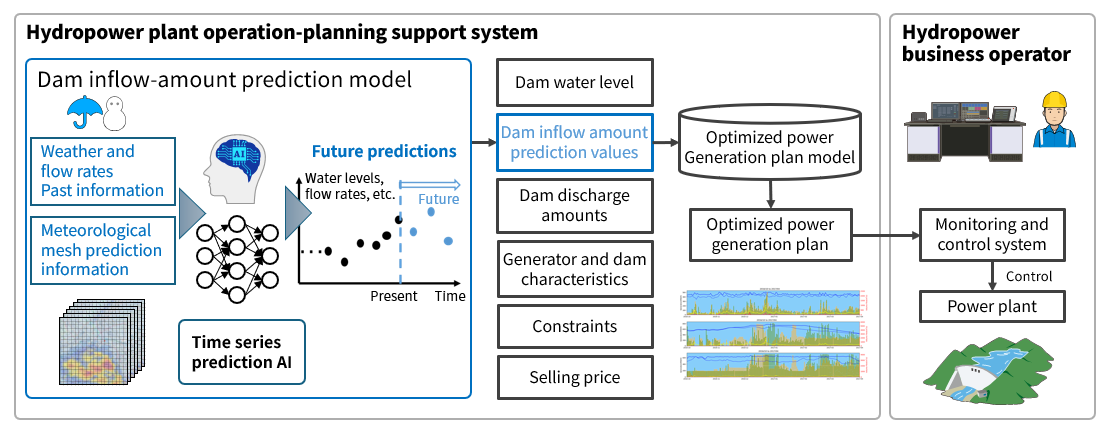

Hydropower plant operations support system

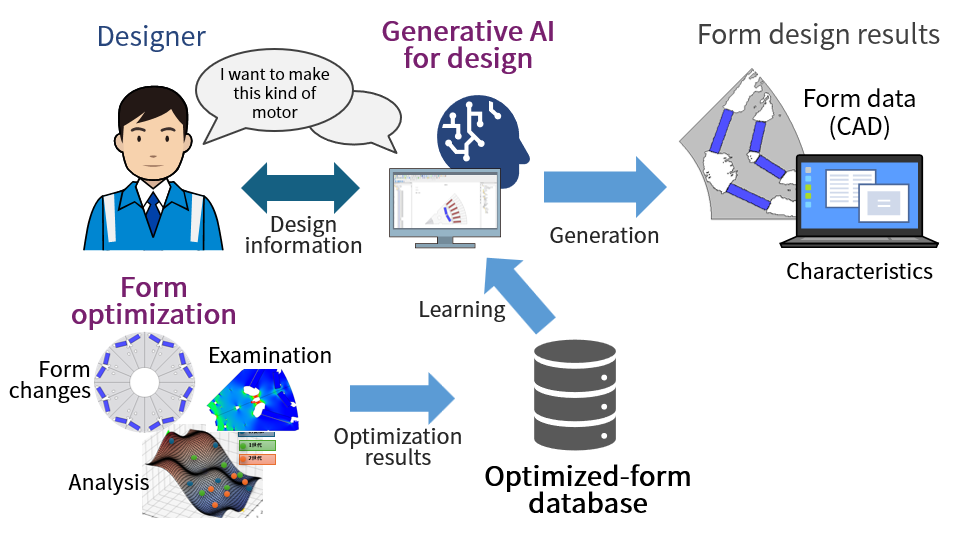

Automated design system for motors that utilizes form-optimization and generative AI technologies

By combining form-optimization technologies and generative AI, it is possible to automate and speed up motor design work. Generative AI taught with optimized design data can create and propose optimal motor forms in just a short time based on the designer’s specification requirements, thus revolutionizing the traditional design process which relies on trial and error.

- AI utilized for ultra-precise predictions of dam inflow amounts based on future weather information

- Maximizes power generation amounts through efficiency improvements based on power generation operation plans, dam water-level changes, etc.

- Provides both flood countermeasures and stable electric power supply

- Reduces workload demands on operators and helps reduce the risk of future losses of technical knowledge in light of declining birthrates

Design automation system

Hydropower plant operation-planning support system utilizing AI time series prediction technology

This system utilizes AI technology to predict future weather and flowrate changes based on time series data and improve hydropower plant operating efficiency. The AI learns about relationships between weather information and dam inflow amounts and, achieving a shift from operations reliant on past operating experience to data-based, optimized power generation plans.

- Generative AI rapidly produces optimized motor designs based on the designer’s specification requirements

- Form-optimization technologies produce high-performance design results that surpass those of traditional approaches

- Design automation reduces labor demands and significantly shortens development times

- Promotes digitalization of design know-how and preservation of technical skills for passing on to future generations