Material Technologies

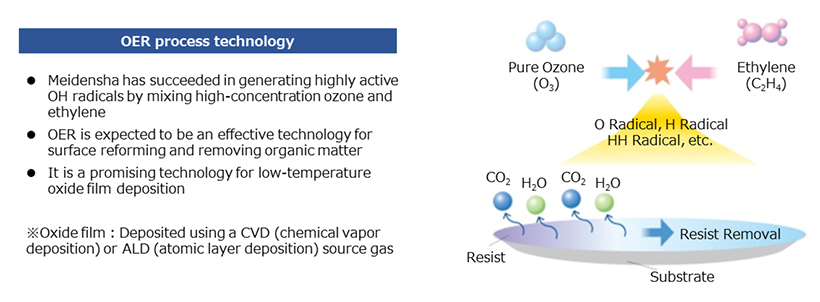

Product development grounded in material characteristics is essential since Meidensha products are often used under harsh conditions for extended periods. This page discusses the material technologies behind the vacuum circuit breakers that shut off high voltage instantly, and the surge arresters used to protect equipment from lightning strikes or other abnormal voltages. It also looks at Meidensha’s original room-temperature deposition process technology enabling deposition with atomic layer deposition (ALD).

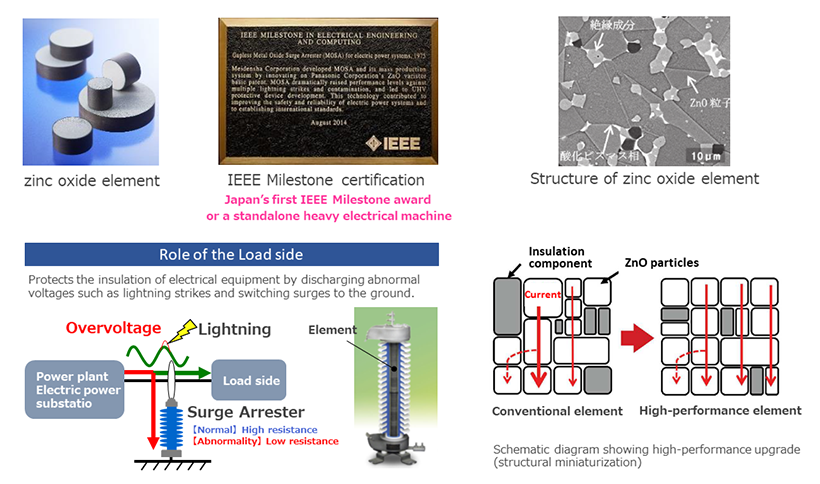

Zinc oxide-based semiconducting ceramic elements

Surge arresters that protect grids from lightning strikes and other abnormal voltages work by drawing on the characteristics of these semiconductor ceramic elements. These elements release abnormal voltages to the ground by lowering their resistance only when abnormal voltages are received. High reliability is ensured by using specially devised material components and firing conditions to create elements composed of fine uniform particles.

Improved and specially devised additive formulation, raw materials properties and firing conditions

- Controlled additive concentration (giving zinc oxide particles improved electrical conductivity)

- Reduced insulation components, controlled reaction of insulation components (increasing surge current pathway)

- Uniform microstructure (providing uniform current pathway to reduce current concentration)

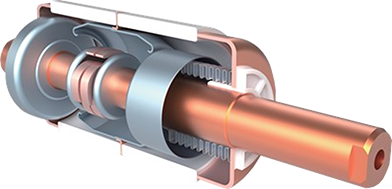

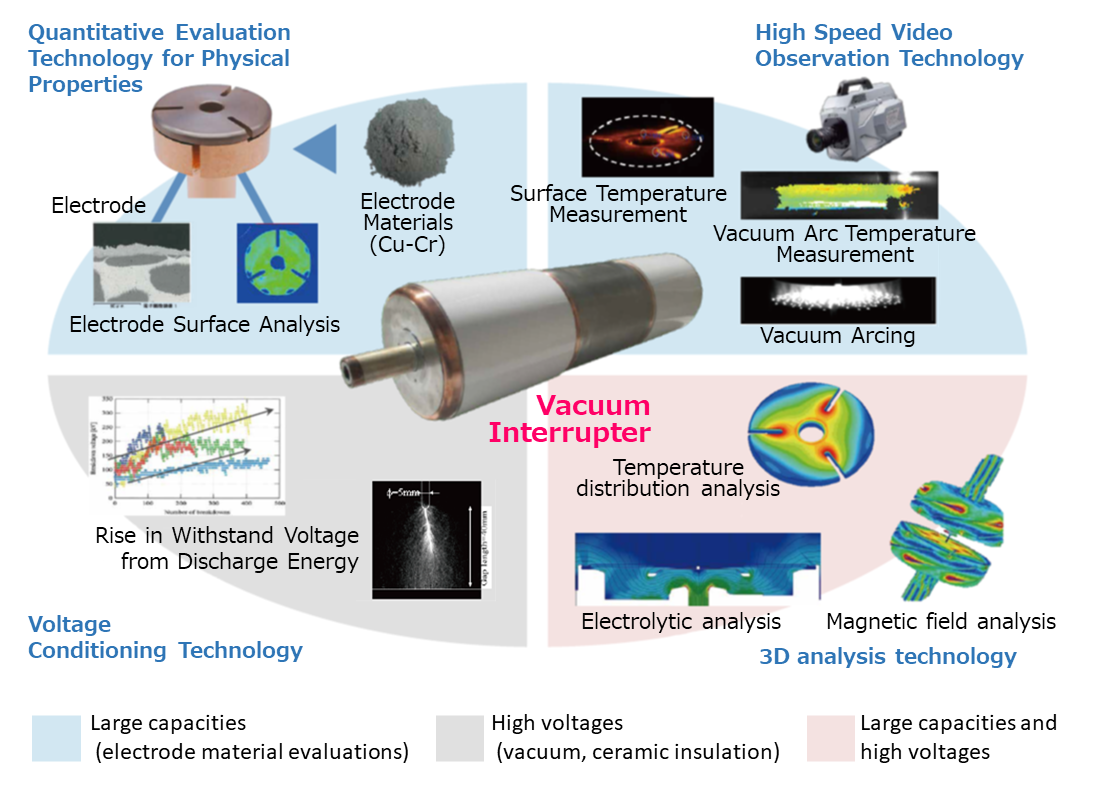

Fundamental technologies underpinning development of high-voltage, large-capacity VCBs

Fundamental technologies for VIs

Vacuum interrupters (VIs) are key components used in the vacuum circuit breakers (VCBs) that temporarily shut off the flow of electricity in a power transmission network. VCBs safely shut off the electricity by using vacuum power to extinguish the arc generated when the two VI electrodes are separated.VI electrode performance is underpinned by a wide range of fundamental technologies such as electrode surface state analysis, observations of vacuum arc disappearance during operation, and three-dimensional analysis of magnetic fields, electrolysis and temperature distributions.

Drawing on analysis and assessment technologies to evaluate and optimize the metal structures of electrode materials

①Improving electrode quality by quantitatively evaluating the physical properties of electrode materials

②Using high-speed video-based observation to describe electric current cutoff behavior

③3D analysis technology-based structural optimization

・Magnetic field analysis

・Electrolysis analysis

・Temperature distribution analysis

④Using technology for optimizing voltage conditioning energy to create VIs with smaller designs and higher withstand voltage

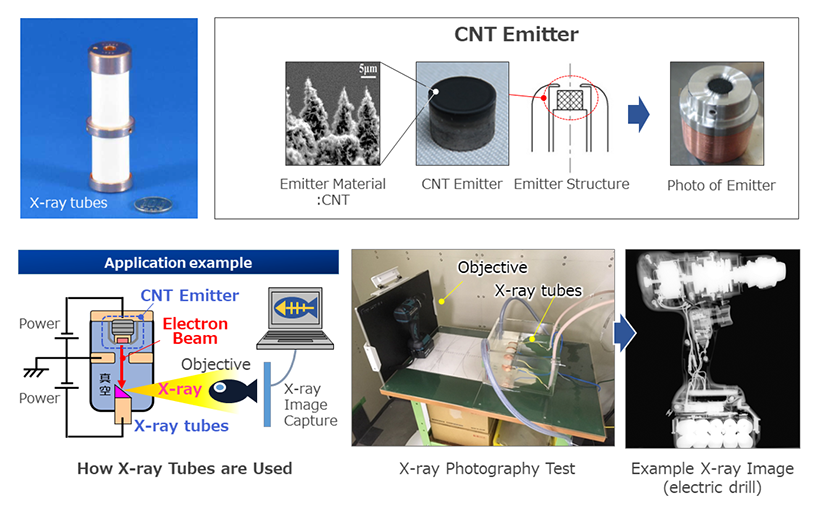

Vacuum tubes that generate X-rays. Use VI/VC vacuum technology and X-ray tube emitters containing CNTs (carbon nanotubes)

Use nanocarbon materials to reduce the size of the X-ray tubes that emit X-rays in the scanners commonly found at facilities such as airports. Other applications are also foreseen for CNT cold cathode X-ray tubes, such as non-destructive inspection of infrastructure equipment and plant piping.These specialty products combine new material technologies and Meidensha Corporation’s portfolio of vacuum technologies such as vacuum capacitors and vacuum interrupters.

Features

①Smaller and lighter than heated filament method

②Enable power-saving, long operational life

Applications

Used in security, industrial and medical applications

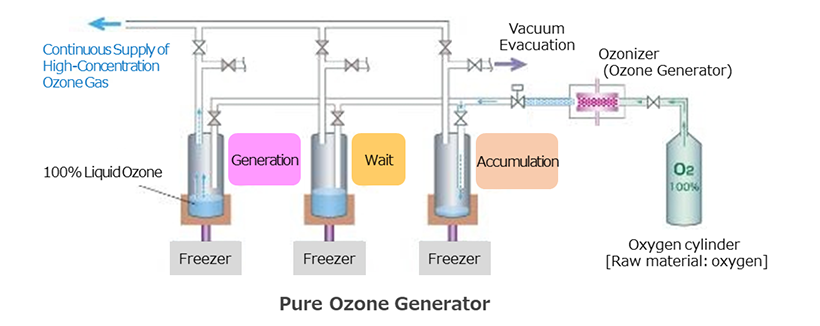

Devices that safely and continuously generate high-purity (≒100%), high-concentration ozone gas

This device generates, stores and supplies high-purity, high-concentration “pure ozone.” It utilizes safe equipment design based on the approach of preventing dangerous reactions through pressure reduction.

Characteristics

- Ozone generated by an ozonizer is liquefied at an extremely low temperature to create pure ozone

→Ozone concentration of 80% or higher - Enables on-demand provision of pure ozone anytime, in just the amounts needed

- Reduces contaminant NOX to 10 ppm or less (in certain models only)