Business Areas

Meidensha behind every electricity scene

The light turns on when you press the switch. Water comes out when you turn the tap. These everyday conveniences we take for granted are made possible by infrastructure that has been created, operated, assisted and improved over the years by Meidensha Corporation.

Click below for simple descriptions of Meidensha Corporation’s seven electrical technologies.

Meidensha’s four business groups

Meidensha’s business areas are organized our into four groups as a way to enable business optimization and efficiency. This system lets us respond quickly and accurately to environmental changes or the diverse needs of our clients. Each group responds to a changing world by working on strategies designed to achieve their vision for reshaping it.

Power Infrastructures Business Group

Alongside conventional electric power company business, the Power Infrastructure Business Group focuses on business areas designed to help achieve a carbon neutral economy. It is working increasingly on small and medium-sized hydroelectric power generation projects and O&M projects for hydroelectric and wind power generation. It also focuses on projects providing renewable energy-based solutions. The Group’s overseas substation segment is based in the Singapore market. The Group has also invested in India, Vietnam and North America, where it is working to expand its business and grow earnings.

Power and energy

Power and energyThe Group’s efficient power receiving, distribution and storage systems help ensure a stable supply of power and energy. They include power generating systems using renewable energy sources such as hydroelectric or solar power, and EMS (energy management system) technology designed to make effective use of energy.

Tank vacuum circuit breakers insulated by dry air instead of sulfur hexafluoride gas (a designated global warming gas). Ideal for green procurement driven by the basic concepts of reducing life cycle cost (LCC) and environmentally-friendly criteria—Reduce, Recycle, Reuse (the Three Rs), and Long Use & Separability (LS).

Meidensha Corporation has designed a photovoltaic power generating system that maximizes power conditioning system (PCS) performance. The PCS is the cornerstone of photovoltaic systems, and an area of expertise for Meidensha as a system integrator. Meidensha also provides photovoltaic power generating systems ensuring safe and secure use for extended periods by drawing on the experience and quality expertise we have acquired over the years as a heavy electrical machinery manufacturer constructing public infrastructure.

Meidensha Corporation began manufacturing vehicle-mounted electricity generators in 1968, and we now have about a 70%* share of the domestic market among electric power companies. We have delivered over 1,000 units, including deliveries to other businesses. [*Source: Meidensha Corporation data]

Public, Industrial & Commercial Sector Business Group

Working with clients such as local governments, the Public, Industrial & Commercial Sector Business Group proposes solutions designed to respond to new challenges such as creating wider-area infrastructure services, decarbonization and BCPs (business continuity plans). The Group also focuses on creating business synergies by working with the Field Engineering Group. The Group’s overseas electric railway business segment is working to complete existing projects and improve profitability. New projects designed to sustainably raise the Meiden Group’s profile and help build rail infrastructure are also underway.

Electric rail systems

Electric rail systemsThe Group provides a number of products that help ensure safe and stable rail transport around the world. Examples include AC/DC traction power supplies, overhead line inspection systems that significantly improve maintenance efficiency, and power monitoring systems essential for power system operation.

The Group meets client demands for optimum design by providing everything from ultra-high voltage power receiving and power feeding transformers, to rectifier transformers for Shinkansen line.

Equipment used for high-precision inspection of the requirements for overhead rail line maintenance and inspection. Applies edge detection, model matching and other image processing technology to images of overhead lines captured by cameras.

Power control systems that help ensure a stable power supply for rail transportation require high reliability and real-time performance. Meidensha has created a number of different power control systems that provide high reliability and enable long-term maintenance when used with industrial components made by Meidensha.

Water infrastructure systems

Water infrastructure systemsMeidensha is a general water treatment plant manufacturer with a successful track record of building and refining water and sewage systems throughout Japan. We draw on this track record to design, manufacture and build water treatment plants, while also providing a comprehensive range of support that extends to plant operation, upkeep and management.

Meidensha Corporation’s monitoring and control equipment consists of systems supporting a wide range of water and sewage plants of all sizes. A wide array of optional functions are available in addition to the standard monitoring and control functions, enabling system construction tailored to client needs.

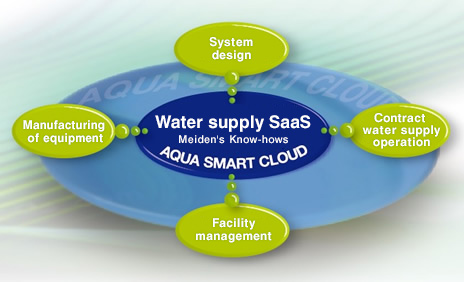

Aqua Smart Cloud is an SaaS* cloud computing service for water and sewer utilities. Aqua Smart Cloud provides outsourced system operation, upkeep and management in addition to the monitoring and control technology and remote monitoring service provided by previous Meidensha services. It also boosts the efficiency of client water supply operations by drawing on the expertise Meidensha has acquired over the years by providing water utilities with comprehensive outsourcing packages.

Meidensha has developed a highly durable ceramic flat membrane that applies the ceramic manufacturing technology the Company has acquired over many years, and makes it possible to propose new types of membrane treatment systems. It is currently being used for industrial wastewater, public sewage and various other applications by users inside and outside Japan.

Plant construction work, hands-on safety education

Plant construction work, hands-on safety educationMeidensha provides high-quality construction for clients representing a wide range of industries in the public and private sectors. Our work draws on construction expertise acquired over many years of building plants inside and outside Japan, along with rigorous safety management and quality control.

Besides installing electrical equipment, Meidensha also provides full turnkey service for construction or civil engineering projects, machinery or equipment installation, and various other equipment construction work. We work on concrete tanks and machine rooms needed in water treatment facilities. We design and construct buildings, anechoic rooms, air conditioning systems and various other equipment needed in vehicle testing facilities.

Meidensha Corporation has been providing employees with hands-on safety education designed to stimulate danger sensitivity since 2008. In December 2016, Meidensha Corporation also began selling on-site education for clients seeking it at plants, construction sites and other locations outside the Company. Hands-on safety education is more effective than other methods, and is helping eradicate workplace accidents. Lessons that simulate the experience of workplace accidents are provided in all-weather hands-on safety education vehicles that eliminate the need for student movement.

ICT

ICTThe experience and expertise Meidensha has acquired over the years are being combined with ICT to help provide and streamline stable public infrastructure.

Meidensha Corporation’s smart maintenance systems are making effective use of the IoT to replace conventional maintenance provided at predetermined times with maintenance provided whenever the condition of the equipment demands it. They are enabling a switch from TBM (time-based maintenance) to CBM (condition-based maintenance).

A real-time monitoring service for sewage pipes. Uses a manhole antenna to enable real-time monitoring of sewer pipe parameters such as water level.

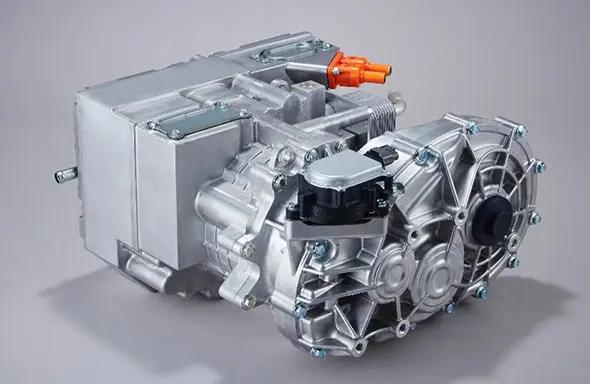

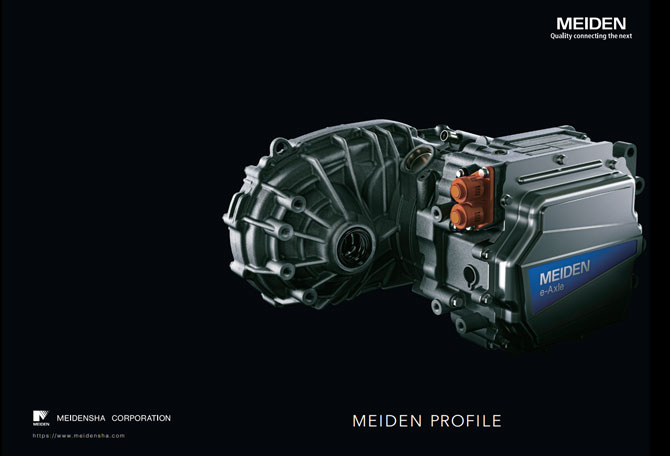

Mobility & Electrical Components Business Group

The Mobility & Electrical Components Business Group’s EV motor and inverter segment is dedicated to helping create a world of clean mobility. Its business activities are designed primarily for the needs of vehicle manufacturers. The Group is working on achieving an EV segment sales target of 100 billion yen for FY 2028 through product development and capital investment. The result will be business growth and investment returns. The Group’s transport segment and semiconductor segment are working on refining advanced technologies and strengthening partnerships. Their activities provide labor- and energy-saving innovations to the industrial sector, helping the world advance to the digitalized era. The Group is focusing on providing digital technology-based smart maintenance systems for industrial parts, growing its environmentally friendly motor sales and its semiconductor product market share.

Industrial components

Industrial componentsMeidensha products are used in a wide range of industrial sectors. Examples include advanced-function communication equipment and motor drive application products such as motors and inverters.

Meidensha Corporation’s PM motors have been well received by users for many years.

Combining advanced technology with the extensive track record and technical expertise Meidensha has acquired over the years, they satisfy user needs for high performance, high quality, labor-saving, energy-saving and a wide range of other areas.

Meidensha Corporation produces the only vacuum capacitors made in Japan. All models are compliant with RoHS (Restriction of Hazardous Substances) directives.

The highly reliable vacuum capacitors developed and manufactured by Meidensha draw on vacuum technology and expertise acquired over 40 years of developing and manufacturing vacuum circuit breakers.

μPIBOC-I industrial controllers are compact models providing improved performance and reliability. Their shape has remained unchanged for eight generations. Meidensha helps ensure stable equipment operation through the use of these industrial controllers.

Mobility

MobilityMeidensha is bringing value to the auto industry by providing emissions gas and fuel economy testing systems, along with the drive systems that underpin the switch to EVs.

Meidensha provides a wide range of products and services for vehicle development, with examples ranging from proposals to plant construction. We have proposed autonomous driving systems, operation measurement control systems, and equipment for testing engines, transmissions, finished vehicles and other products. We have also built test chambers, incidental facilities, testing facilities and other plants with full turnkey construction.

Meidensha develops technologies and products for EV and HEV drive systems by drawing on motor and inverter technology acquired over many years. Meidensha’s drive units with built-in motor gearboxes are more compact, lightweight, efficient and quiet. They provide ample reliability for vehicle installation.

Conveyor system products

Conveyor system productsMeidensha has an extensive lineup of conveyor system products designed for specific cargo types and operating environments, and ranging from low-cost kit types to automatic guided vehicle (AGV) systems. We propose optimum AGV systems designed to meet a diverse range of client needs.

Forklift-type automatic guided vehicles suitable for transporting pallets. Both forward/backward motion and lateral motion/diagonal spin turns come as standard features.

Low-priced AGVs that can be flexibly assembled by the user.

Simple AGVs with high flexibility and expandability. Combine high performance with the low cost of kit products.

Automatic guided vehicles with FANUC collaborative robots collaborative robots able to work alongside human workers. Support both transport and material handling operations in a single unit.

Field Service Engineering Business

Amid growing demand for BCPs, energy saving measures and equipment life extension, the Field Service Engineering Business Group is responding by working to grow and boost earnings from all-in-one services that provide comprehensive packages of electrical equipment services encompassing everything from maintenance and inspection to upkeep, operation and management. The Group is also committed to providing ICT-based smart maintenance services and novel solutions.

Field Service Engineering

Field Service EngineeringMeidensha proposes all-in-one service packages that ensure optimum upkeep, management, maintenance, repair, disposal and renovation throughout the equipment life cycle by using Meidensha’s own equipment diagnostic technology after installation.

Meidensha Corporation’s maintenance services provide upkeep to ensure that equipment continues to function as intended from the time of its installation by the client until being renovated or scrapped. The services also provide improvements designed to further refine functionality or performance. To meet the needs of a circular economy, Meidensha is committed to bringing benefits to the world by providing a diverse lineup of maintenance services for every stage of the equipment life cycle.

The Meiden Engineering Center is a hands-on technical training facility providing a unique, large-scale simulated equipment environment equivalent to an actual site. Using this original equipment, the Center provides an effective educational curriculum designed to train outstanding engineers who can assist clients with safe, secure and efficient equipment operation.

Meiden provides optimum engineering designed to accommodate the needs of clients and the general public throughout an equipment life cycle that starts when specifications are finalized and extends through the phases of production, operation, maintenance and disposal. These activities include the year-round, round-the-clock service provided by the Meiden Customer Center. The Center responds to inquiries about equipment problems for every Meidensha product and user.

Meidensha Profile [Movie]

You can download

the catalog that introduces the business of Meidensha from here.