Global Standard TYPE-iDriving robot TYPE-i RBT-2020

Driving robot TYPE-i RBT-2020 is an industrial robot system, consisting of a portable operating panel and a robot, that automatically drives a vehicle on a Chassis Dynamometer and operates various tests in place of a driver. The system received the “GOOD DESIGN AWARD 2021”, “Red Dot Design Award 2022”, and “iF DESIGN AWARD 2024”.

Product Features

The Driving robot is an automatic operation device, which is used for automatic operation of vehicles on Chassis Dynamometer. Accelerator, clutch, transmission, brake and ignition key are operated with electric actuator and they can be operated with test running patterns in the same manner as performance by a human. This robot can be shared with multiple Chassis Dynamometer facilities due to its add-on oriented design and potable design.

- Easy interface with the existing test facility.

- Portable operating panel to enable use on multiple facilities.

- Less wiring.

- Using flat cable enable vehicle door to be closed.

- The robot can be operated with a setup time of 5 mintes.

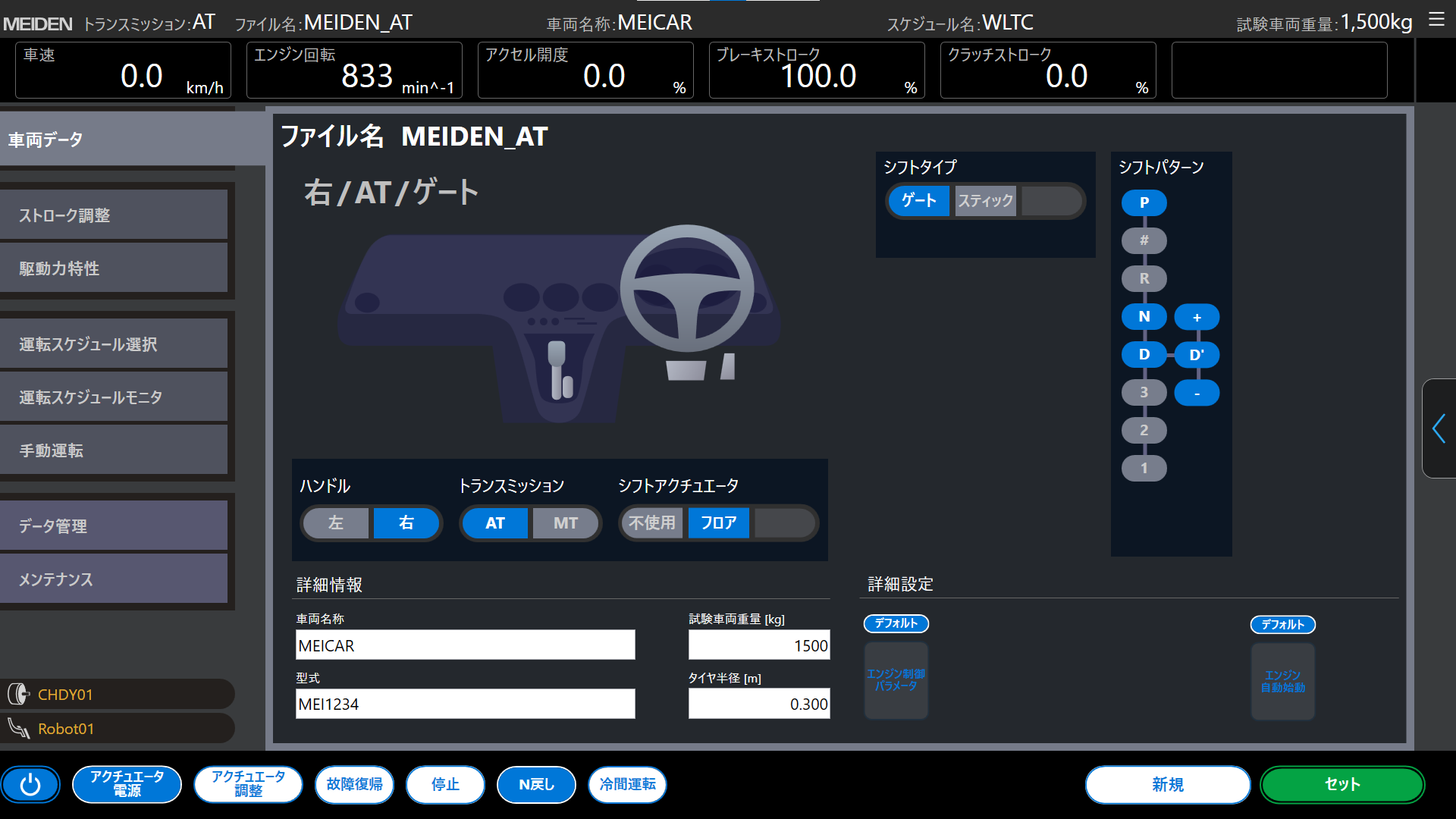

- It supports right/left-side steering, A/T, M/T, floor and column shifter.

- It realizes the professional driver level operation performance.

- High-precision operation in compliance with various regulations

- Quick retrieve target data from accumulated big test data.

- Capable of testing under low pressure, low temperature, and high temperature environments

Applications and Solutions

Specifications

| Item | Specifications |

|---|---|

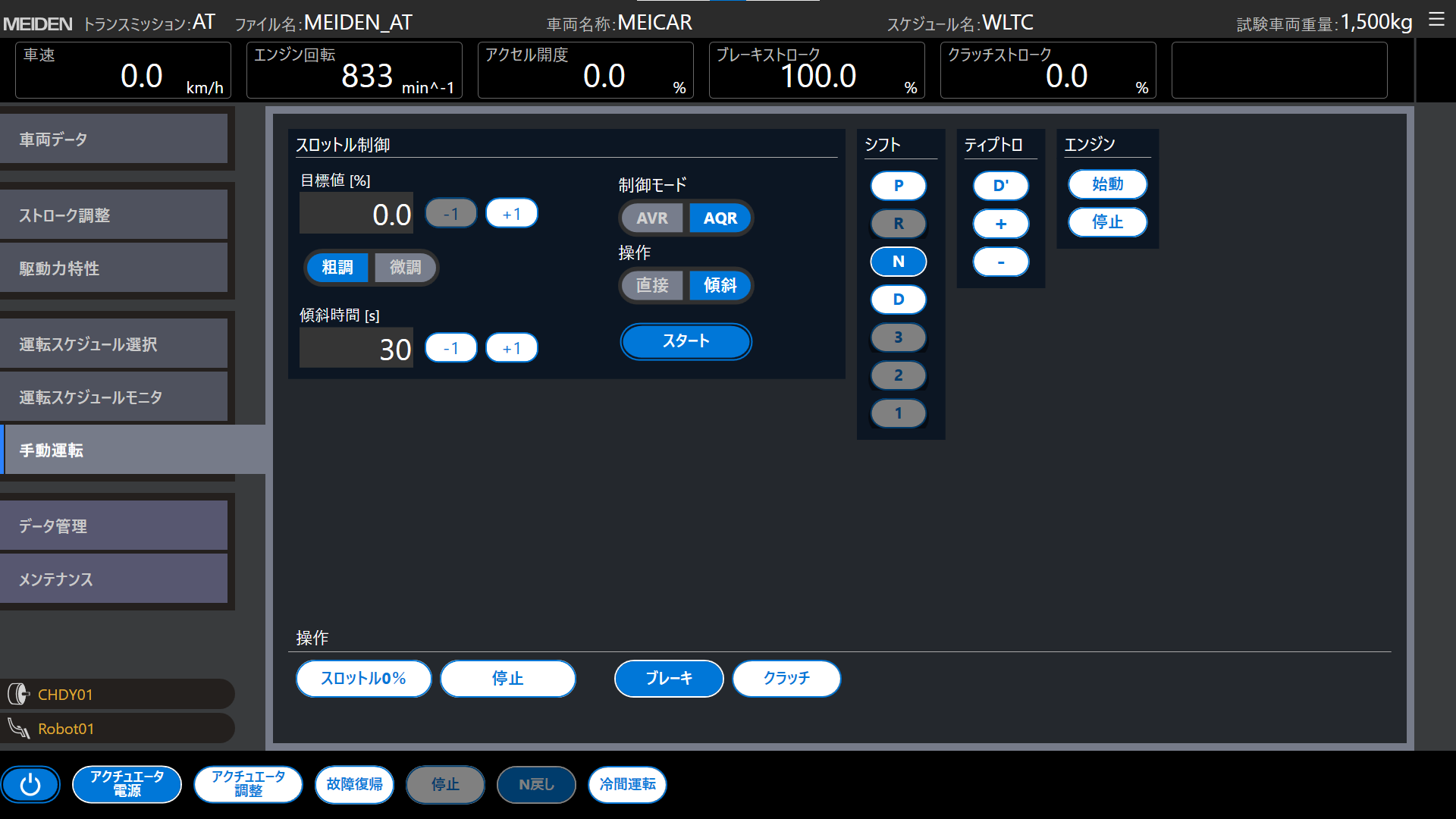

| Operation functions | Automatic/manual operation Vehicle speed control (time, distance based) Throttle position control Brake on/off Clutch engage/disengage Shift position selection Actuator stroke range adjustment |

| Learning functions | Driving force characteristic recording Transient characteristic recording |

| Weight | Actuator: approx. 23.5 kg (including frame, shifter, accelerator , brake and clutch actuator) Control wagon: approx. 106 kg |

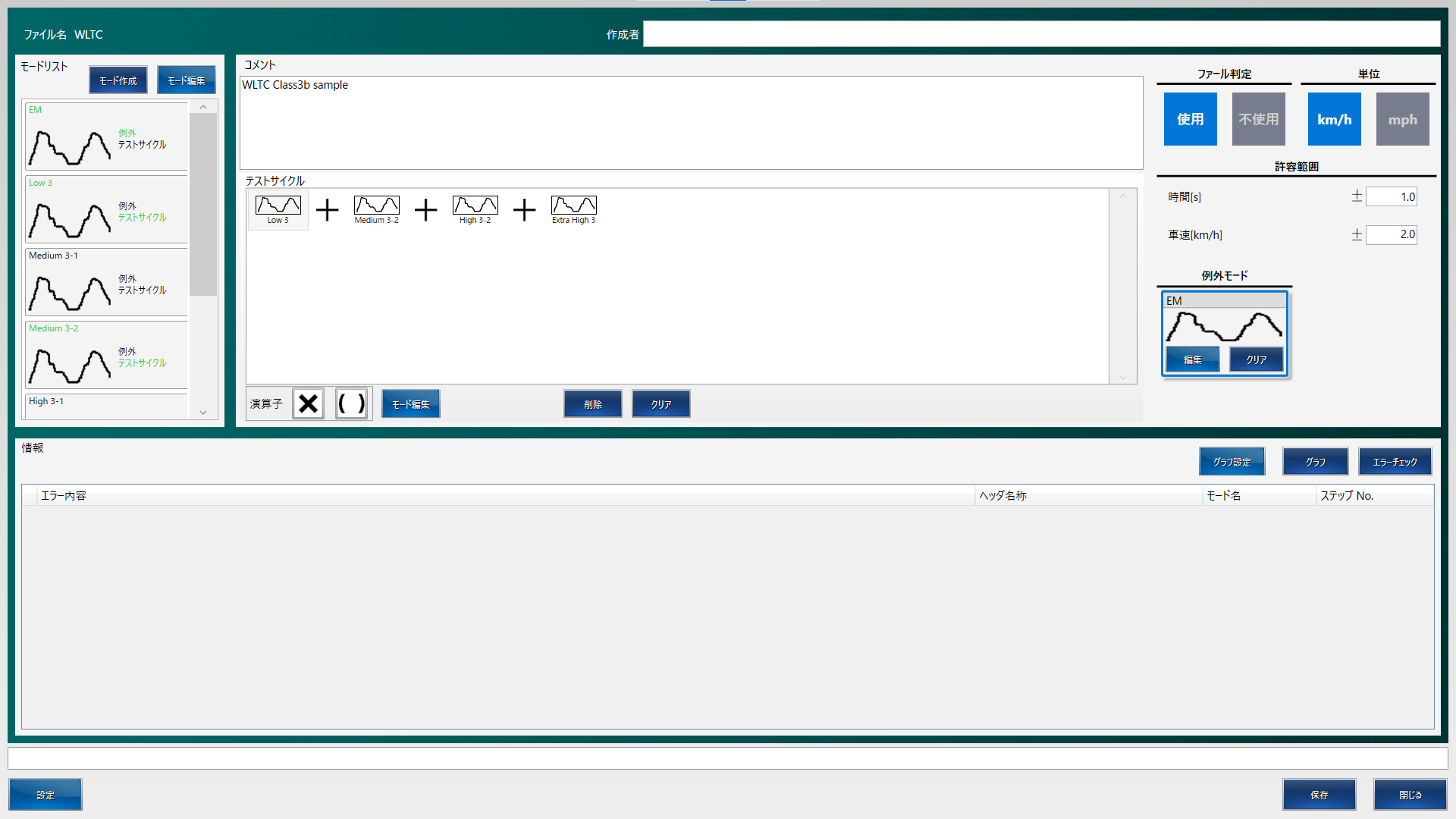

| Editing functions | Operation schedule editing One mode, approx. 200,000 steps Foul judgement function Step transition conditions (time, distance, measurement) |

| Display functions | Analog display, digital meter, bar graph, trend graph |

| Measurement functions | Sampling cycle minimum of 1 ms Scheduler link function Data output (CSV/MAT/ATFX) General-purpose AO output OBD information measurement |

| Operating environment | Actuator: -40 to 70°C, RH30 to 80% Operating panel: 0 to 40°C, RH30 to 80% |

| Options | Seat cover, instrument holding arm & chucking |

Operation screen

Award history

- Received the GOOD DESIGN AWARD 2021.

The GOOD DESIGN AWARD is the only comprehensive design award in Japan. It is the successor to the Good Design Product Selection System established by the Ministry of International Trade and Industry in 1957 and subsequently taken over by the Japan Industrial Design Promotion Association (currently the Japan Institute of Design Promotion).

* GOOD DESIGN AWARD : https://www.g-mark.org/en/learn/what-is-gda

- Received the Red Dot Design Award 2022.

The Red Dot Design Award is an international design award established in 1955 and sponsored by the Design Zentrum Nordrhein Westfalen in Essen, Germany.

* Red Dot Design Award : https://www.red-dot.org/- Received the iF DESIGN AWARD 2024.

The iF DESIGN AWARD is an international design award for the promotion of design, founded in 1953 and organized by iF International Forum Design GmbH, based in Hanover, Germany.

* iF DESIGN AWARD : https://ifdesign.com/en/- Inquiries about this product