Low voltage motor driveHighly functional general purpose inverter THYFREC VT240S

Next generation inverter with 6 control modes for global markets

-

- Auto tuning

- Its auto tuning function makes the task-free on roublesome motor constants setting. It can make the best tuning even to the other supplier's existing motors.

-

- High efficiency operation

- During the light load operation, the motor automatically lowers the output voltage and suppressesthe no-load loss of motor. In so doing, it improves the overall energy efficiency.

-

- Operating ratio setting

- It is a computing function on the gain and bias against against the frequency setting value. It is applied when multiple motors are operated with a different speed in the production line.

-

- Frequency jump

- It can operate the motor avoiding the mechanical resonance point of the motor at the specified frequency. It is effective during the V/f control.

-

- Drooping setting

- The load can be balanced when multiple motors that are mechanically linked are operated. It becomes effective in the vector control and PM motor control modes.

-

- Program frequency setting

- Several types of frequency setting can be fixed, and it is a useful function when there is no need to make the setting value linear. It can be operated by switching the frequency setting of the sequence externally in case the necessary steps of the operation frequencies are set in advance.

-

- Multi-pump operation

- Multiple pumps can be operated in parallel with one inverter.

-

- PID control

- A feedback loop of the analog inputs can be configured as feedback.

-

- Pattern operation

- It is operated by automatically switching the frequency, the driving direction, and the time.

-

- Traverse operation

- Patterns suited to winding threads uniformly in a spinning system are operated optimally.

-

- Simple ASR function

- Simple speed control can be performed by installing the speed detection option even when the V/f control mode is selected. High accuracy speed control is possible with simple adjustment.

-

- Spinning frame operation

- Pattern operation for spinning is performed. Unlike pattern operation, the acceleration and deceleration to the next setting are started right after the setting frequency is achieved. The pattern operation can be restarted from the frequency and the time at stopping after the power recovery when there is a power failure.

-

- S-shaped cushion

- Speed changes can be made smooth to alleviate the sharp impact at acceleration and stopping.

-

- Instantaneous restarting

- Even the inverter operation stops during the power outage, its instantaneous stopping and restarting function can search the free-runninng motor rotation frequency after power recovery and match the output frequency and the voltage. In so doing, it can automatically restart the operation.

-

- Dynamic braking

- During the deceleration, the motor operates as a generator when operated from the load side and electric energy is generated. Braking force is made available by dissipating the energy as heat in resistor.

-

- DC braking

- By applying the DC power to the motor to produce the energy, braking force can be obtained by dissipating the produced energy as heat.

Product Features

This inverter is applicable for various purposes from the energy-saving operation of fans and pumps to steel production lines requiring high precision and high response. This inverter is equipped with an LCD panel equipped with displays in 5 languages and supports voltages throughout the world, thus this inverter can be used globally. With six control modes, both the induction motor and PM motor can be controlled. A built-in PLC (programmable controller) is provided as standard equipment. Load on the sequence circuit and controller outside the inverter are reduced. 16 models of 200 V series: 0.7 kW to 90 kW and 24 models of 400 V series: 0.7 kW to 475 kW are serialized.

- All-in-one inverter with 6 functions

- Equipped with built-in PLC

- It meets with the leading world requirements.

- Environmentally friendly

Applications and Solutions

Fan/blower

Energy saving

A substantial energy saving effect can be obtained by changing the damper control of dust collecting blowers, exhaust fans, boiler forced draft fans, etc. to the rotation control by an inverter.

Further, it realizes energy saving by controlling the air flow of air conditioning systems / gas pressure feed systems at factories, etc., according to the season or to demand changes.

Automation

The air flow and the pressure are automatically controlled by a boiler forced draft fan, a gas pressure feed system, etc. depending on the operations or the demand.

Reduction of noise

The noises of power transformers, gas pressure feed blowers, etc. installed in urban areas, etc. can be reduced by decreasing the rotation when demand decreases in the middle of the night or depending on the seasons.

Pump

Energy saving

A substantial energy saving effect can be obtained by changing the flow control of the pump by a discharge valve to the rotation control by an inverter.

The flow of underwater pumps, cooling pumps, etc. is controlled depending on the season or demand change to implement energy saving.

Automation

The flow rate and the pressure are automatically controlled by cooling water pumps or factory water feed pumps etc. depending on the operations or demand.

Conveyor

Improving efficiency and performance

Efficiency is improved while suppressing dust generation by changing the speed according to the type of the product being transported on a conveyor. The conveyance amount can be controlled by changing the speed of the conveyor, and the compounding ratio of the raw materials can be controlled by adjusting the cutting-off amount.

Automation and rationalization

The speed and the conveyance amount can be automatically adjusted by the type of the product being transported on a conveyor. Further, the acceleration and deceleration time can be optimally controlled in order to prevent load shifting of the product being transported on a conveyor.

Cart

Automation and rationalization

Stopping accuracy at a fixed position improves by applying an inverter and driving it at a stable low speed. Further, the occurrence of shock can be eliminated by using a cushion start.

Extruder

Automation and rationalization

The speed, the discharge amount, and the discharge pressure can be automatically adjusted by the type of material.

Specifications

| Application motor | 0.4 - 475kW |

|---|---|

| Max. continuous rated current | 200 V series: 5.0 to 328 A |

| 400 V series: 2.5 to 870 A | |

| Overload capacity | 120% 1 min, 150% 1 min |

Please feel free to contact us for the specifications that are not shown in this table. Please use the Internet inquiry form.

Control mode

This inverter is equipped with 6 control modes and can thus drive IM and PM motors with a single unit.

- V/f (fixed torque) control mode

- The generated torque of the motor can be constant in a wide range of variable speed driving. It is applicable to extruders, conveyors, etc.

- V/f (reduction torque) control mode

- It is ideal for a square reduction torque load with small torque in the low speed range such as fans / pumps.

- Vector control mode with sensor

- It can respond to demands for high response, high accuracy, and a broad range of speed control. It is ideal for main driving of film lines, steel processing lines, etc.

- Vector control mode without sensor

- This mode is not equipped with speed sensor and enables higher accuracy speed/torque control compared to V/f control. Fourth quadrant operation can be performed smoothly.

- Control mode for PM motor with sensor

- The PM motor is driven to implement high efficiency driving. It can be applied not only to square reduction torque such as fans and pumps but also to a constant torque load, and energy can be saved more efficiently compared to the induction motor.

- Control mode for the PM motor without sensor (see note)

- The PM motor can be driven without speed sensor and highly efficient operation is realized.

(Note): Please contact us by Internet inquiry form regarding sensorless PM motor control mode.

Globally operable

This inverter is the global model which meets the world leading standards, communications protocols and major languages displayed on the panel.

- This equipment is manufactured in accordance with the requirements of the UL and cUL.

- It comes with RS422/485 serial port as standard. Its applicable protocols are Meiden 's original protocol as well as Modbus-RTU.

- Applicable to major networks in the world including PROFIBUS-DP, DeviceNet, CANopen and CC-Link. (Option) (Note)

- For the LCD operation panel, 5 languages including English, Spanish, Italian, German, and French can be displayed.

- For supply voltage, 200 V series: 200 to 240 V (011 L or less) and 400 V series: 380 to 480V are supported.

- (Note):

- PROFIBUS-DP is a registered trademark of PROFIBUS User Organization.

DeviceNet is a registered trademark of ODVA in the US.

CC-Link is a registered trademark of Mitsubishi Electric in the US and Japan.

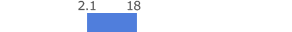

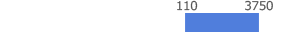

Quick reference table

This is a quick reference table showing the ranges of each series motor voltage and capacity of the motor . Just one look, you could see our offerings.

| Category | Models | Voltage | Output (kw) | |

|---|---|---|---|---|

|

||||

| Low voltage motor drive | THYFREC VT240S | 200 V/ 400 V Series |

|

|

| THYFREC VT800 |  |

|||

| Related products | THYFREC CV240S | 200 V/ 400 V Series |

|

|

| High voltage motor drive | THYFREC VT710S | 3000 V/ 6000 V Series |

|

|

| THYFREC VT710P (with a regenerative power function) |

|

|||

| THYFREC VT730S |  |

|||

| THYFREC CV700SB | Secondary voltage: 1570V |

|

||

- Inquiries about this product