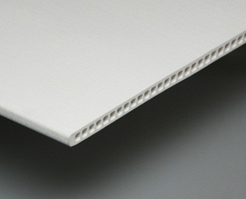

Industrial wastewater treatment systemsCeramic flatsheet membrane

For conventional membrane treatment systems, high replacement frequency due to clogging and rupture of the membrane (filter) has been an issue. Drawing on our long-standing engineering resources on the ceramic product manufacturing technology, we developed a highly durable "ceramic flatsheet membrane" to address these issues.in order to realize our proposal for a new membrane bioreactor (MBR) systems. This system is very effective for wastewater including oily and solvent and inorganic wastewater including hard solids. This system has been utilized in various plants at home and abroadincluding industrial wastewater and public sewage.

Features

This system offers combined features of ceramic and flatsheet membrane and such features are not available in the conventional membranes.

- Multipurpose

This unit can be applied to various wastewater containing solvents, oil, chemicals and/or suspended solids. - Robustness

This membrane has high resistance to chemical damage and thermal degradation. - Maintenance saving

Daily maintenance can be reduced with automatic cleaning control. - High recoverability

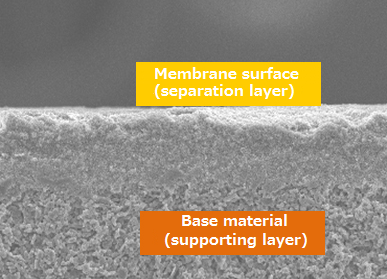

Surface of membrane has resistance to dirt and dirt can be removed easily from the surface, so this unit can maintain its filtration performance long. - Energy saving

Sheet-form arrangement and air dispersal method facilitate more effective air scrubbings.

Ceramic membrane bioreactor requires low amount of scrubbing air thereby reducing energy consumption.

Brochure Download

Social Media

Case Study

- Inquiries about this product