Growing and Applying Core Technologies

History of Meidensha’s technology and business growth

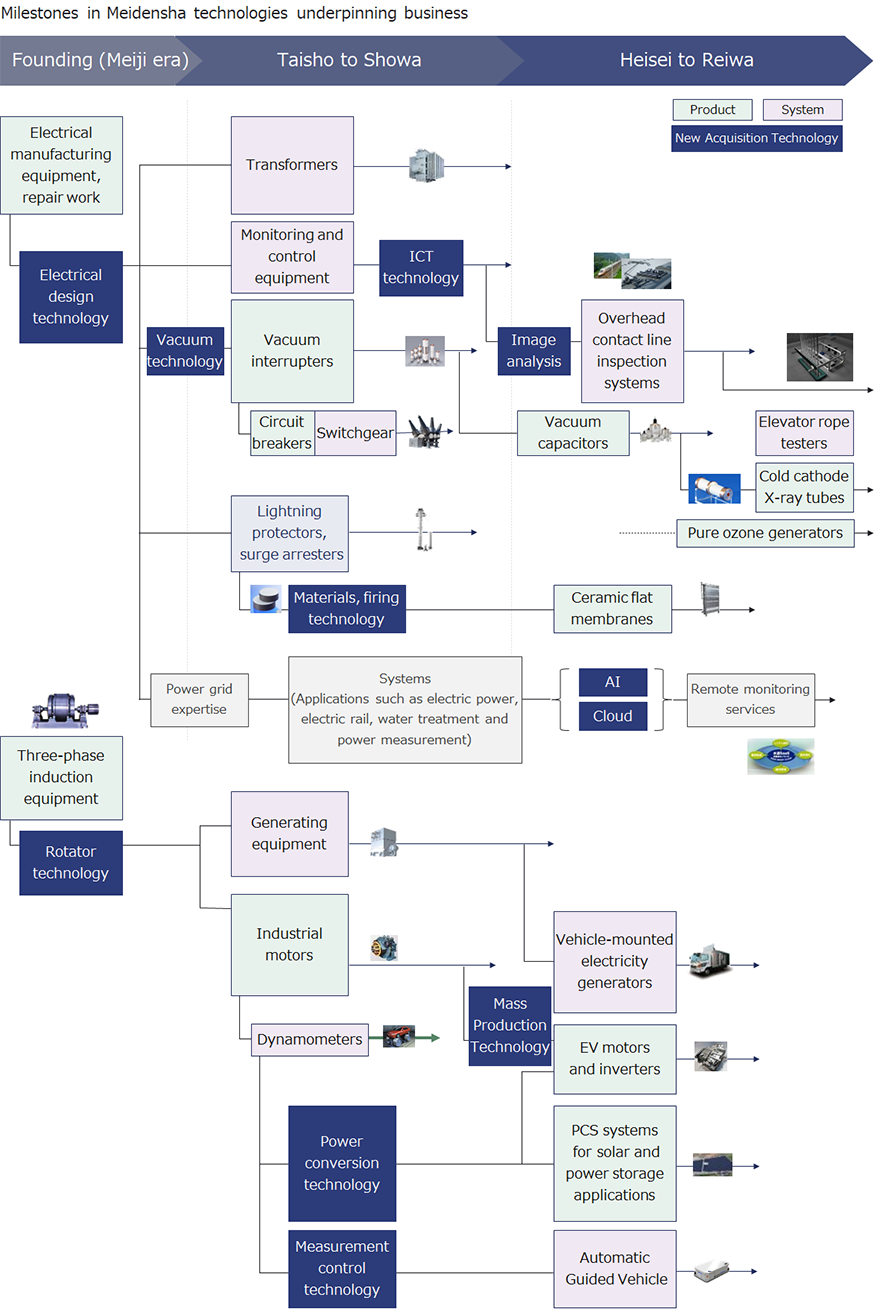

Meidensha has been repairing electrical design technology, rotators and generators while producing small switches and lighting equipment since our founding. In later years, we developed a three-phase induction electric motor made in Japan, and expanded our business to start manufacturing electric motors, generators, transformers and switches. We also work on automotive testing devices and equipment monitoring and control systems (our mainstay product areas). These products have recently led to the creation of derivative outgrowth products and services that are designed to help solve issues of public concern—overhead line measurement equipment, elevator rope testers, vehicle-mounted electricity generators and AGVs.

A lineup of Meidensha Corporation technologies rooted in electrical design technology and rotator technology has been pioneered or acquired to meet the needs of these derivative products. Examples include technologies for vacuums, material firing, power conversion, measurement control, ICT and image analysis.

Core technologies

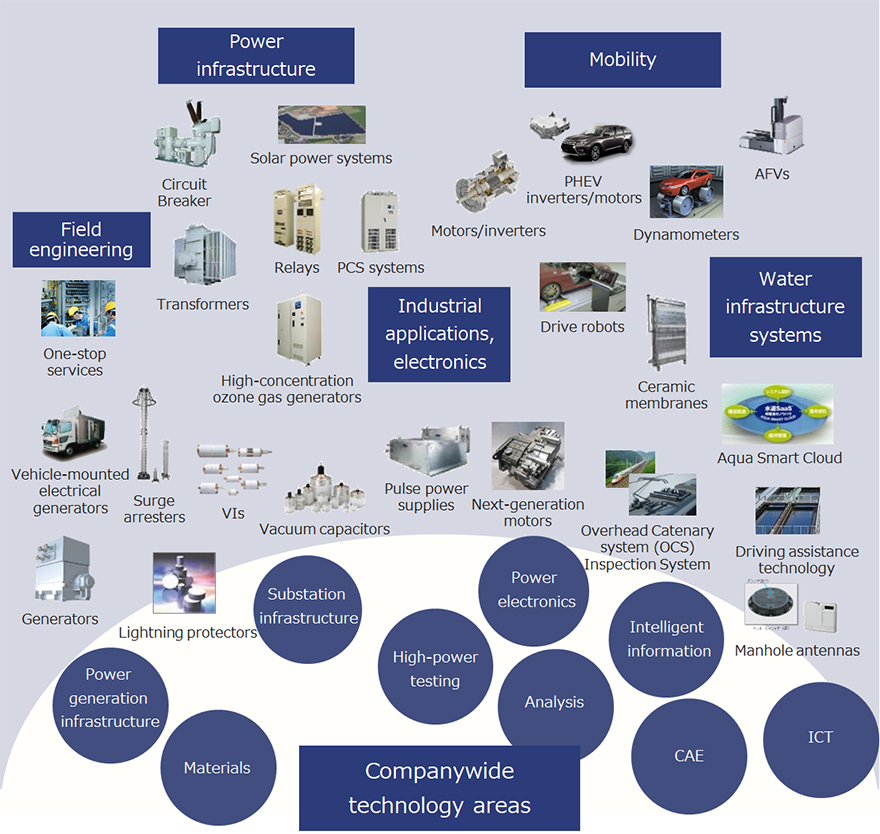

Meidensha Corporation does business in the areas of power infrastructure, mobility, industry & electronics, water infrastructure systems, and field engineering. The wide array of products and services we provide in these areas are underpinned by R&D Division technologies in the areas of power electronics, intelligent information, materials and common fundamental technologies. Read on to find out more about Meidensha’s R&D work and latest technologies.

Power electronics

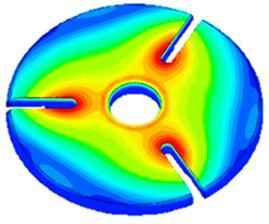

Power electronics is the technology used to convert the power obtained from a power plant or renewable energy source into a usable form for end users. Substation equipment and EV drive systems are also made possible by power electronics technologies. Substation equipment is essential for a stable power supply. EV drive systems convert electrical energy stored in batteries into the power that drives EVs. This page looks at some examples of power conversion technology and EV drive system design technology.

Intelligent information technology

Meidensha is developing intelligent information technology as a way to apply AI (artificial intelligence) to our business areas. AI creates new value by learning from various observations made about equipment, serving as a substitute for human workers. This page presents AI technology created to address the issue of dwindling populations, drive robot control technology providing accurate vehicle road test simulations, and image recognition-based monitoring technology for rail line equipment.

Material technologies

Product development grounded in material characteristics is essential since Meidensha products are often used under harsh conditions for extended periods. This page discusses the material technologies behind the vacuum circuit breakers that shut off high voltage instantly, and the surge arresters used to protect equipment from lightning strikes or other abnormal voltages. It also looks at Meidensha’s original room-temperature deposition process technology enabling deposition with atomic layer deposition (ALD).

Common fundamental technologies

This page describes the common fundamental technologies underpinning the reliability of Meidensha’s core products. Common fundamental technologies are overseen by our Analysis Center, Quality Assessment Center and High Power Lab. The Analysis Center provides analysis and CAE to assist design work. The Quality Assessment Center uses a number of different analysis technologies to help improve product quality and prevent defects. The High Power Lab provides performance check testing for heavy electrical products. The page below provides a brief description of each facility.