Intelligent Information Technologies

Meidensha is developing intelligent information technology as a way to apply AI (artificial intelligence) to our business areas. AI creates new value by learning from various observations made about equipment, serving as a substitute for human workers. This page presents AI technology created to address the issue of dwindling populations, drive robot control technology providing accurate vehicle road test simulations, and image recognition-based monitoring technology for rail line equipment. This page presents AI technology created to address the issue of dwindling populations, drive robot control technology providing accurate vehicle road test simulations, and image recognition-based monitoring technology for rail line equipment.

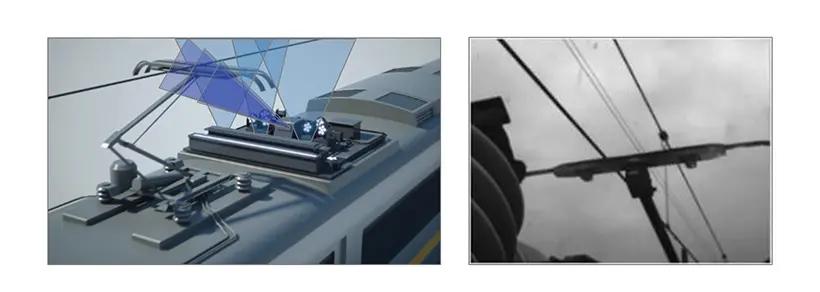

Diagnostic systems for rail line equipment (image-based diagnostic systems)

Catenary Eye (camera image-based analysis system)

- Measures contact wire height, deviation, wear, hard spots and contact force

- Detects rail line equipment problems

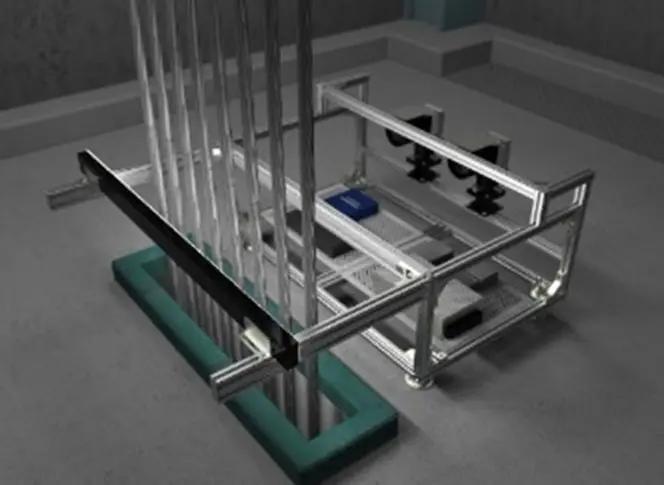

Elevator rope testers (image-based diagnostic systems)

Use image-based analysis technology to inspect elevator rope condition

Apply rolling stock line equipment diagnostic system technology

- Enable measurement during high-speed elevator travel

- Measure parameters such as narrowing and deformation over entire rope length in a single operation

Driving robot

Simulated vehicle road performance testing

Deep reinforcement learning

<Inputs>Engine speeds, speed commands, other

<Outputs>Estimated accelerator and brake operation levels

Highly accurate vehicle performance assessment testing (for driving modes)

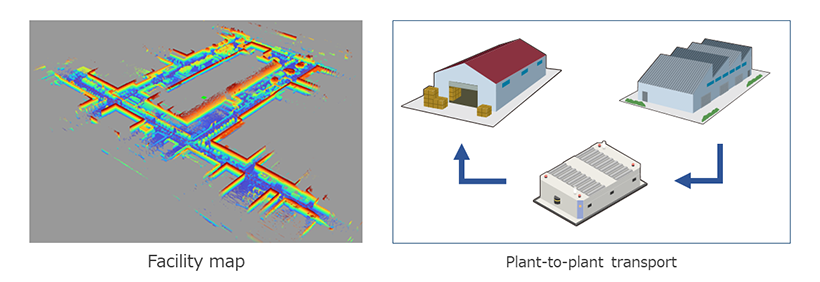

3D spatial recognition system

3D-SLAM automated outdoor plant-to-plant transport system

Automated assistance for water treatment system operation

AI-based operation assistance

- Uses machine learning to automate the control of operation amounts for sewage treatment tanks

- Helps the next generation of master technicians acquire skills