Improvement Maintenance

Functional improvement and energy saving are intended.

Improvement of function and energy saving

Along with our actions for the improving reliabilities of equipment life, we promote functional improvements

(measures taken against harmonics and noise) and energy saving (improvement of power factor).

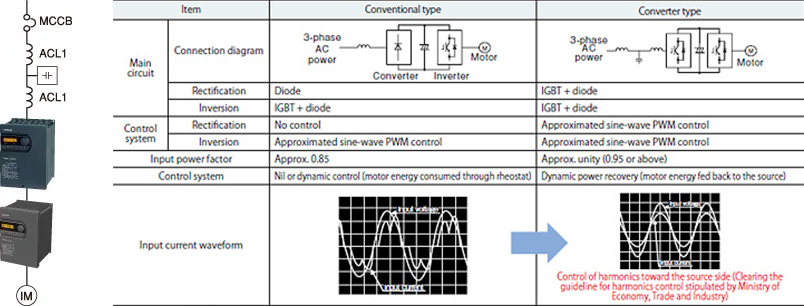

1. Advantages of renewal to converter controller.

Inverter VT240S LB535-3090

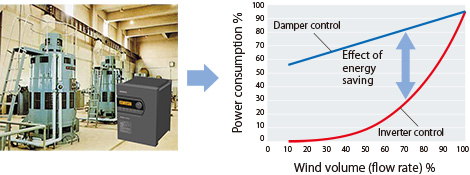

2. Energy saving for fans / pumps and environment-friendly operation are possible

When inverter control is adopted for fans and pumps, a great effect of energy saving can be attained compared to damper control.

For example, as shown in the figure on the left, when operation is performed with the speed reduced by 30%. The required power can be reduced from 80% to 30%. Thus reducing energy consumption and CO2 emissions.

Is there any product which is difficult to maintain?

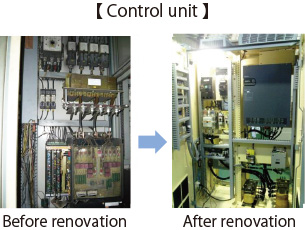

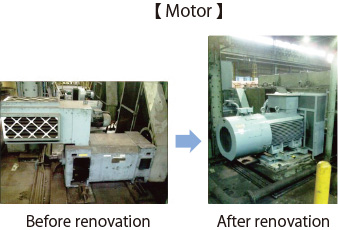

Even for products made by other firms and/or those imported from foreign countries, it is possible to improve reliabilities of equipment life and improve functions through the adoption of inverters for equipment including motors.

Examples; An electrical apparatus manufactured overseas was improved/ renovated using Meidensha inverter.

Countermeasures for the environmental effect

Countermeasures against corrosive gases : Photo-catalyst type corrosive gas decomposer.

Protects your devices from corrosive gases in the installation environment. Our CL110 decomposes corrosive gases by using a photocatalyst.

Example of application

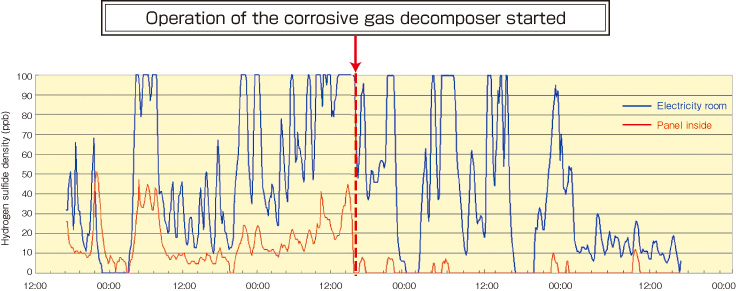

The following case demonstrates the purification performance of our corrosive gas decomposer.

In the sludge concentration chamber of a certain waste water treatment plant, the concentration of hydrogen sulfide gas in switchgear was measured with and without operating the corrosive gas decomposer.

The results are shown below.

- *Caution notes for corrosive gas decomposer

This equipment is effective only in a closed space. It is specified to reduce the effect of corrosive gases.