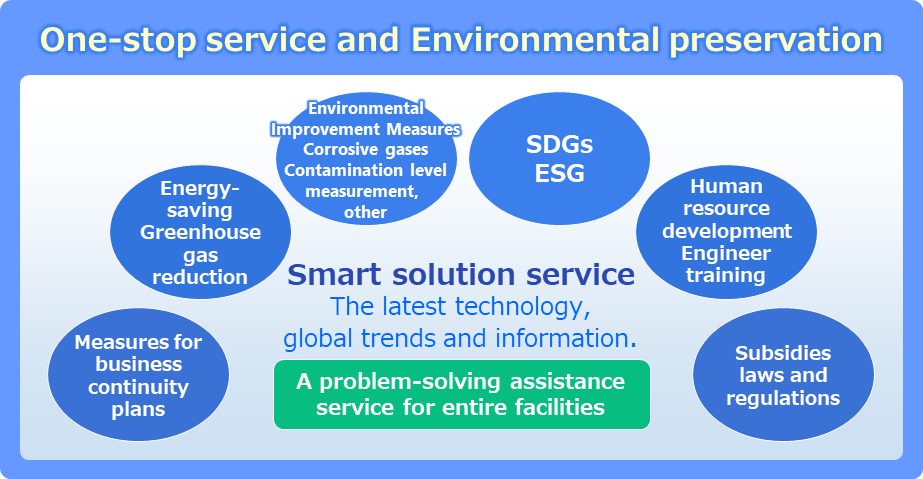

One-stop Service

One-stop service of Meiden Engineering

Meiden Engineering provides one-stop service covering everything from detection to resolution of problems in client electrical and other equipment.

We help ensure client business continuity by providing walkthroughs to detect issues, and smart solutions to solve them.

- GHG (Greenhouse Gas)

- SDGs (Sustainable Development Goals)

- BCP (Business continuity planning)

- ESG (Environment, Social, Governance)

Walkthroughs

A problem detection service provided with participation from the client. Meiden Engineering works with the client to investigate site equipment and report any operational risks that have gone undetected during routine maintenance and inspection.

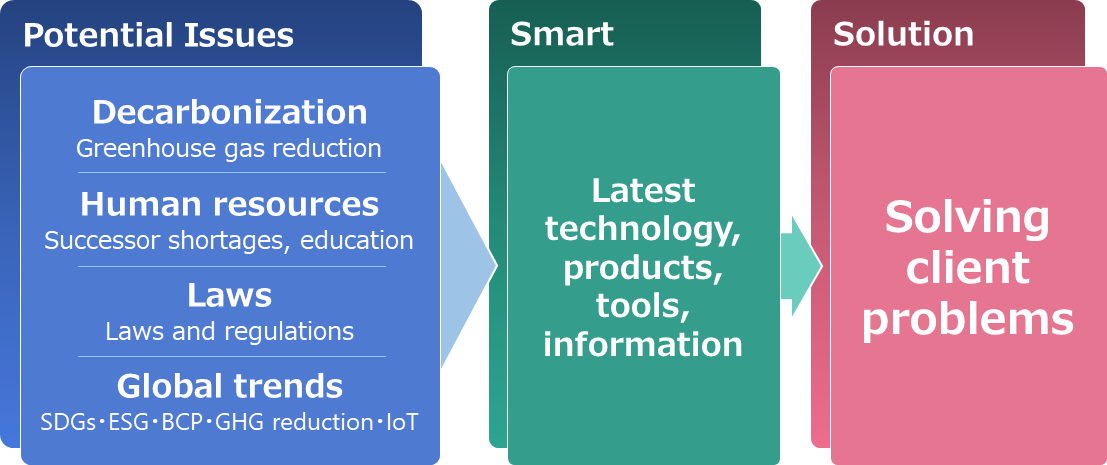

Smart solution service

A problem-solving assistance service. Meiden Engineering helps ensure client business continuity by solving issues detected during walkthroughs. Our solutions are provided by combining the expertise we have acquired over the years as a maintenance provider with the latest technology, global trends and information.

Decarbonization (reducing CO2 emissions)

Improving operations

ICT/IoT-based solutions

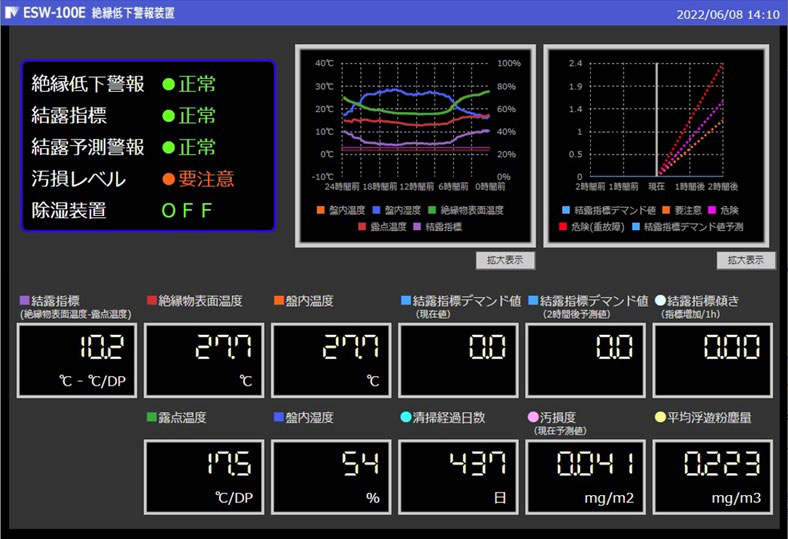

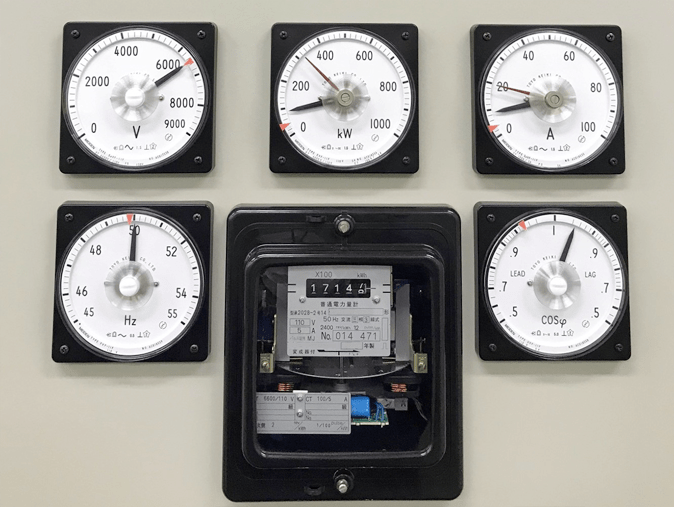

- By visualizing graphically depicting energy consumption makes it possible to monitor consumption in real time and share operation information.

- Meiden Engineering uses IoT technology to collect several types of data, remotely monitor equipment and facility statuses, and boost operation efficiency over a wide area.

- The equipment installation environment is measured to diagnose the risk of equipment failure from environmental improvement measures or equipment deterioration, and to help plan equipment renovations and part replacement.

Power capacitors (power factor improvement)

- Electricity base charges can be reduced by controlling the power factor and reviewing power capacitors to ensure a proper match with the equipment capacity.

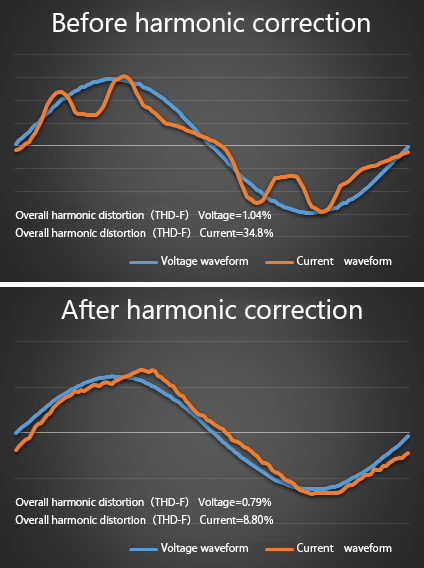

Measures against harmonics

- Active filters can be installed to prevent vibrations, buzzing and abnormal overheating caused when harmonics are generated in equipment such as phase-advance capacitors and series reactors. Active filters can also prevent equipment malfunctions and failures.

- Data monitoring and recording systems can be visualizing graphically depict the harmonics that cause equipment failures and malfunctions.

Measures to reduce building heat and air conditioner loads

- Shielding and insulating equipment from the heat of direct sunlight reduces air conditioning equipment loads and power consumption.

Equipment improvement

Transformers

- Measuring equipment power consumption and selecting the optimum transformer (capacity) can save equipment energy.

- Upgrading transformers to higher-efficiency models reduces power loss.

Electric motors

- Replacing electric motors with models conforming to Japan's Top Runner standards improves energy consumption efficiency.

- Switching to inverter control optimizes motor speed and reduces power consumption.

Air conditioners

- Optimizing the control of components such as warm and cold water pumps reduces power consumption.

- Providing automatic cleaning for condensers (tubular heat exchangers) prevents cooling efficiency drops caused by contaminant buildup.

Cooling towers

- Descaling cooling water improves cooling tower efficiency and reduces power consumption.

- Monitoring cooling tower states and using mechanical and chemical cleaning methods prevents cooling performance drops.

Workforce development, engineer training

- Meiden Engineering helps clients create educational videos designed to provide the next generation of workers with the equipment management expertise of experienced engineers.

- We provide electrical facility maintenance training and education to clients delivered Meidensha Corporation equipment.

Laws and regulations

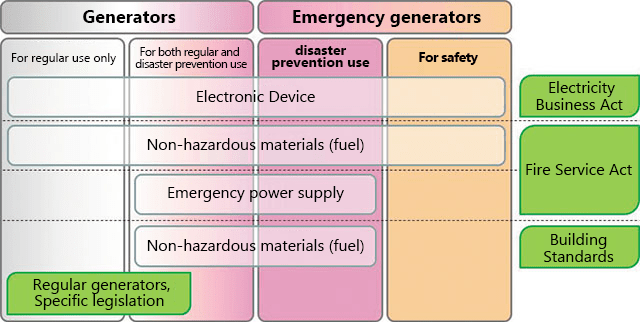

Power generation facilities

- Meiden Engineering provide clients up-to-date with the latest laws and regulations, and proposes legally compliant equipment operation methods, problem solutions and renovations.

- Fire Service Act

- Electricity Business Act

- Building Standards Act, other

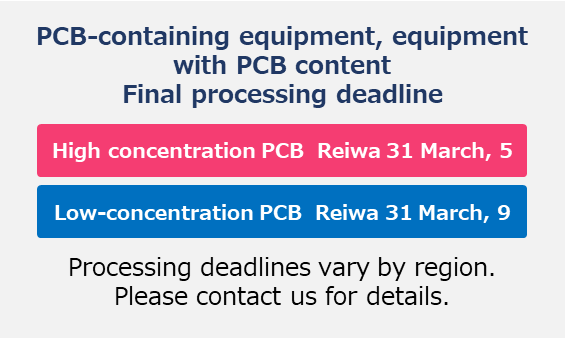

Hazardous substances

- Meiden Engineering checks for harmful substances adverse to equipment or health effects, suggesting solutions when detected.

- Equipment containing PCBs

- Equipment using asbestos

- Equipment containing mercury

- Corrosive gases, other

Global trends

Measures for business continuity plans (ensuring emergency power supplies)

- Meiden Engineering helps clients create measures for disaster-readiness business continuity plans by selecting emergency power supplies tailored to individual applications.

- Installing emergency power generating systems

- Installing vehicle-mounted electricity generators (mobile private power generators in the form of trucks with a prime mover and generator)

Subsidy assistance

- Meiden Engineering helps clients cut equipment installation costs by selecting subsidies optimized to their needs (provided by organizations such as national and local government agencies).

Meiden Engineering can also help solve problems in areas not shown here, so get in touch with your nearest Meiden Engineering representative. Our team is always eager to discuss your needs.