Necessity for Maintenance

In order to prevent system failures and assure stabilized operation, maintenance services by professional engineers are indispensable. These engineers are required to possess sufficient technical expertise in regard to equipment and facilities.

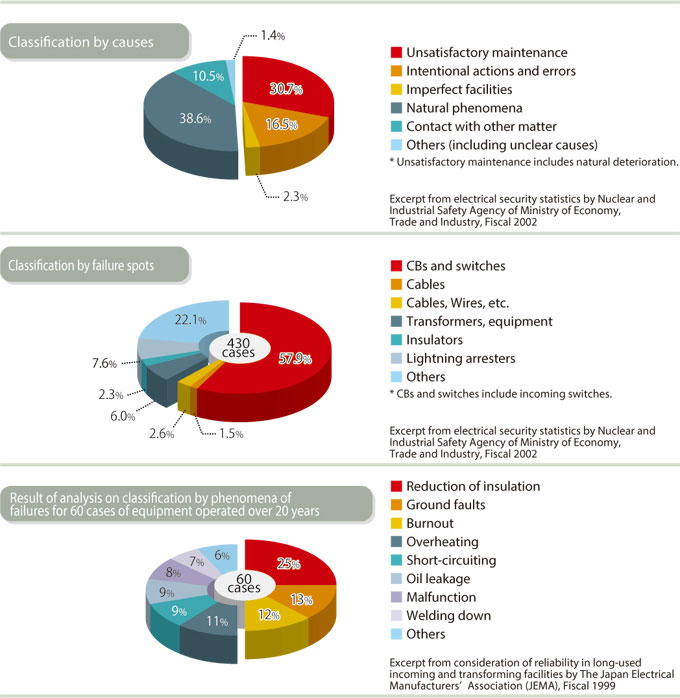

Failure statistics

Present failures in electrical systems

- 01Causes are classified into the categories of unsatisfactory maintenance, intentional actions, errors, and imperfect facilities.

- 02In more than half of all cases, failure spots are mostly located in circuit breakers and switches.

- 03The phenomena of failures result from the reduction of insulation, ground faults, and burning.

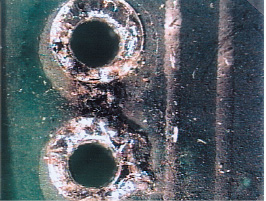

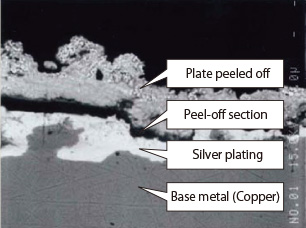

Examples of failures and deterioration

The following photos show typical accidents of each equipment.

Power reciving substation facilities

Excerpt from consideration of reliability in long-used incoming and transforming facilities by The Japan Electrical Manufacturers' Association (JEMA), Fiscal 1999

Rotating machine facilities

These are examples of failures caused by deterioration.

Conductor silver plating peel-off is caused by sulfuric corrosion.

Short-circuiting in printed circuit board caused by copper migration