Maintenance Consulting

We propose an optimum maintenance plan based on various diagnosis.

Maintenance processes

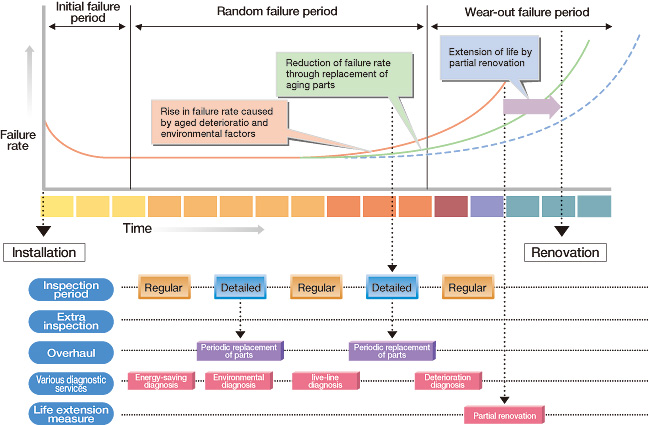

Lifecycle maintenance plan

Table of maintenance plan

Based on the operation mode of facilities and operating environment, we propose adequate types and periods of inspection as well as timing for replacement of parts.

Example: Table of maintenance plan for high-voltage power receiving substational system

- [Outline of facility]

-

- C-GIS: Main and standby incoming lines in a 2-bank configuration

- Transformer: Oil-filled transformers 2 units

- *〇 Regular inspection ◎ Detailed inspection

Periodic replacement of parts will be performed in the second detailed inspection.

Facility deterioration diagnosis is executed in the 20th year to determine the time for renovation.

Environmental diagnosis

Some environmental conditions of installation locations for various equipment units are liable to cause corrosion, rust generation, and deformation in materials of the parts used. Such phenomena can directly affect the occurrence of equipment failures and reduction of operational life. We are ready to investigate environmental conditions of the location of installations and also evaluate the environment of equipment installed. Based on the result of the investigation, we can provide adequate proposals to our customers.

Measurement of corrosive gases

Fujitsu Quality Laboratory Ltd. /

Eco-checker

- 01Intermittent measurement

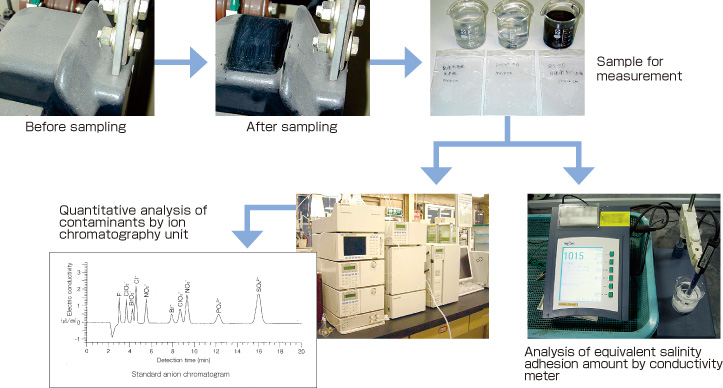

Based on the measurement results of field temperature, humidity, and gas elements (sulfur dioxide, nitrogen dioxide, hydrogen sulfide, chlorine, ammonia) , including the contamination degree, an evaluation of the environment is carried out. Gas elements are analyzed by sampling gases on site. This measuring method is based on JEITA* IT-1004.

*Japan Electronics and Information Technology Industries Association - 02Continuous measurement

Using a gas monitoring unit, temperature, humidity, corrosive gas density, and presence of floating dust are measured continuously for more than a month. Based on the result, we examine the degree of influence of various environmental parameters on equipment on site.

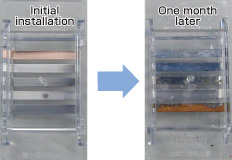

- 03Corrosion-sample measurement

The progress rate of corrosion is confirmed by placing a sample on site for the during of a month at the longest. From the result the corrosive gas density is estimated.

Measurement of contamination degree (dust)

For the evaluation of floating dust (and debris) around the location of installation, measurement and analysis of the contamination degree are carried out. Based on the concrete data obtained, we offer proposals and suggestions to our customers.

- *Meidensha Corporation possesses public approval for [Registered Organization of Measurement Certification Business] and [Organization of Working Environment Measurement].

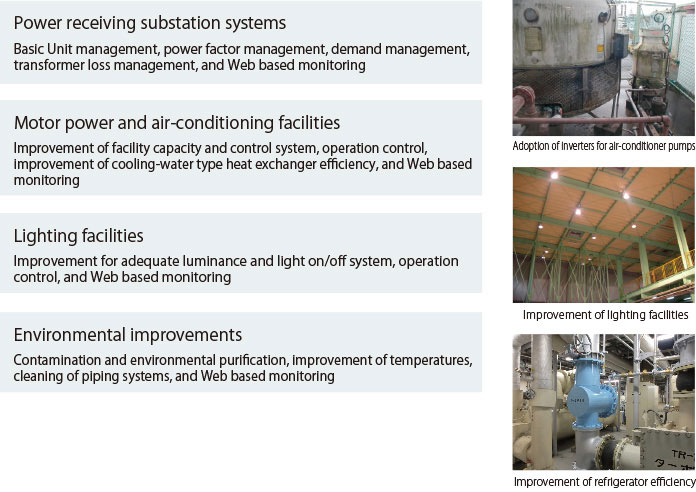

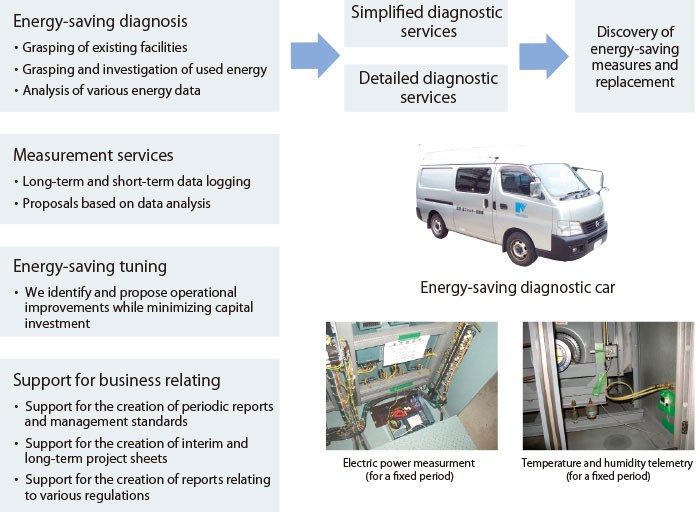

Energy-saving diagnosis

Support for energy-saving measures

We offer effective proposals on the basis of sufficient investigation through energy-saving diagnosis and practical measurements.

Energy-saving measures taken for objective facilities