Facility MaintenanceMaintenance service for power conversion facilities

We perform maintenance, repair, and fault recovery at an early stage to ensure that uninterruptible power supplies, DC power supplies, and all other power conversion products used in our customers' most important facilities are always in sound condition. Through our maintenance service, we also recommend periodic replacement parts and promptly notify customers of signs of parts deterioration, and make appropriate proposals for preventive maintenance and life extension measures. We utilize our accumulated maintenance technology and remote monitoring know-how to provide maintenance services that satisfy our customers.

Features

- Test operations, maintenance, and repairs of all power conversion products.

- Provision of a menu of inspections (round/annual) and maintenance (parts replacement) by high quality expert engineers to keep our customers’ most important facilities in sound condition at all times.

- Proposal of measures to extend the life of equipment and technical advice.

Malfunction Case Studies

・Storage cell battery deterioration/burnout

Storage cell batteries used in uninterruptible power supplies and DC power supplies are important backups for customers' critical load facilities in the event of commercial or other power outages, and require regular maintenance. In addition, if storage cell batteries are used beyond their operational life or are not maintained, there is a risk that they will not function as a backup during power outages due to battery burnout or deterioration of battery function.

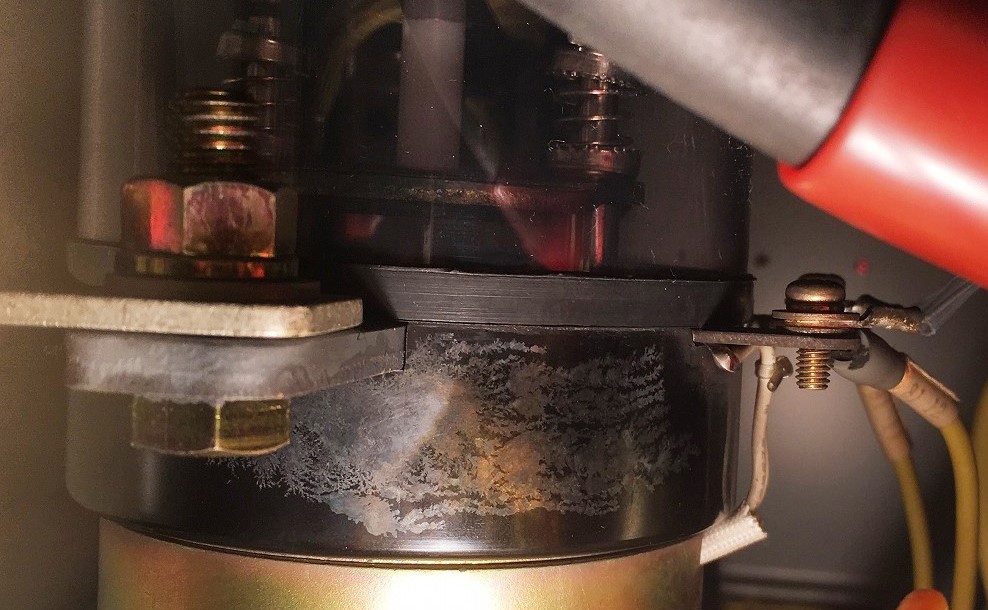

Storage cell battery burnout

Storage cell battery degradation

・Silver migration

Silver migration may occur in the DC part of the insulation material used in the internal parts of the equipment due to installation environmental conditions (high temperature, high humidity, sulfide gas) or long-term use. Visual inspections enable early detection and replacement to prevent short-circuit accidents.

Silver migration①

Silver migration②

Maintenance and inspection

We provide high-quality, highly reliable, and optimal all-facility maintenance and inspection services with the maintenance technology we have cultivated over the years.

1)A variety of inspection service menus offered to suit customers’ needs.

Example: Uninterruptible power supply inspection standards (digital machines) Refer to Table-4 (CA04).

2)Protective relay testing and board instrument calibration can be performed as a special service upon request.

Please contact us for any additional inspection items or requests.

3)Creation of maintenance plans according to the installation environment and operating conditions.

4)Development of optimal maintenance plans, taking into account the life cycle of equipment from the start of operation to the time of equipment renewal.

5)Our expert engineers make proposals for improvements and modifications, and provide support with high quality technical capabilities.

Inspection Service Menu

Insulation resistance measurement

Output voltage waveform measurement

Control power supply voltage measurement

Comprehensive operation test

Technical support service information

Click here for the details of the maintenance services and locations of Meiden Group.

- Inquiries about this product