Power Receiving Substation Systems

The power receiving and transmission facilities that support the infrastructure of society must always be stable and reliable.We provide services from the customer's perspective by utilizing our maintenance techniques and abundant know-how cultivated over many years to support the formulation of preventive maintenance plans (inspections, repairs, and renewals) according to maintenance history management, the current status of equipment deterioration, and the operating environment so that our customers' facilities can always be operated in the best possible condition.

Features

- Our high-quality technicians take responsibility to ensure that customers can use the facility with peace of mind.

- Engineers with expertise in the equipment perform maintenance, and based on accumulated data, establish appropriate inspection cycles and times for parts replacement to support the overall life cycle of the facility.

- We develop various propriety maintenance tools to enable inspections and diagnostics that were difficult to conduct in conventional working hours.

Facility Maintenance and Inspections

An unforeseen event in the power receiving and transmission facilities can have serious implications, including building power outages and plant shutdowns.

In addition, it is important to conduct periodic power outage inspections to prevent accidents, as they may impact power companies and other social infrastructure facilities. We undertake maintenance and inspection work to ensure the long-term stable operation of our customers' facilities, and conduct advanced inspections utilizing live-line diagnosis and other methods.

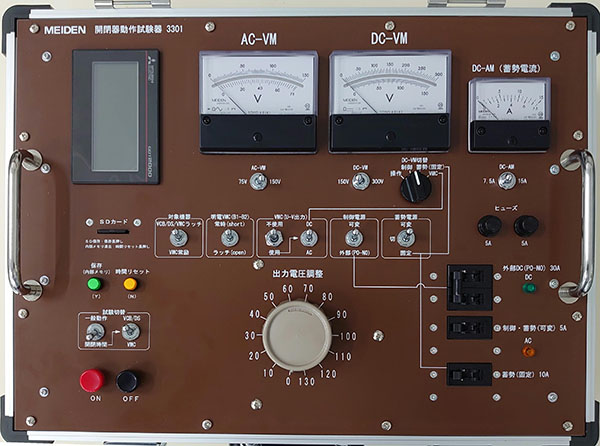

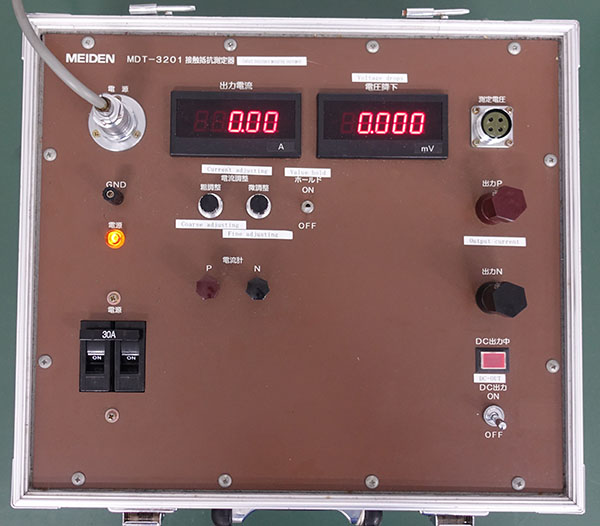

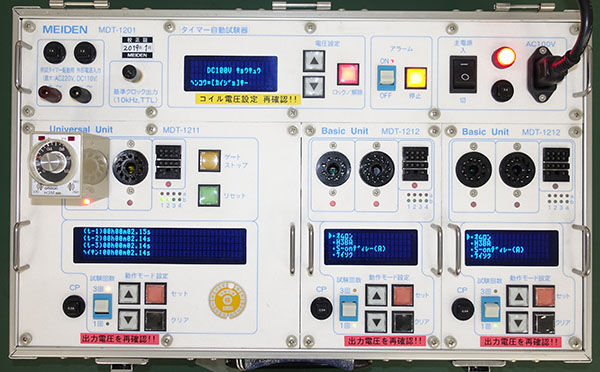

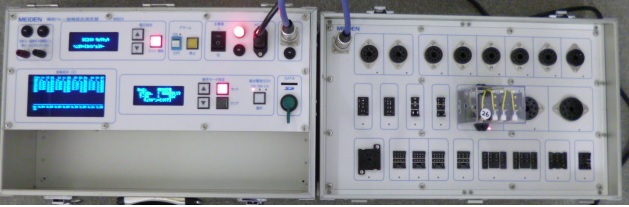

Examples of maintenance work support tools

In order to provide high-quality maintenance services, we utilize a variety of state-of-the-art tools.

(The test equipment shown here are in-house tools and are not for sale to the general public.)

Equipment diagnosis

We contribute to lower risk of failure, maintaining reliability, and optimization of maintenance costs for our customer's facilities by detecting signs of failure in power receiving and transmission facilities at an early stage, and proposing appropriate responses and measures.

Partial discharge diagnosis

We check for harmful partial discharges due to fouling or deterioration of insulation in high-voltage electrical equipment

- Checks for partial discharge by waveform analysis using an AE sensor*

- Checks for the occurrence of partial discharges based on the frequency of captured electromagnetic waves caused by electrical discharges

- Visualization of ultraviolet rays from electrical discharges and identification of locations where partial discharges occur

- *Acoustic Emission (AE) sensor: A vibration sensor using a piezoelectric element

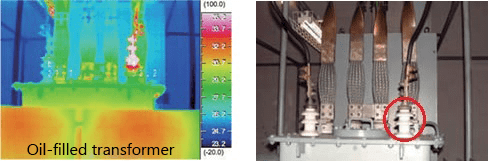

Thermographic diagnosis

We check for abnormal overheating due to deterioration of high-voltage and low-voltage equipment in electrical facilities.

- Checks for abnormal overheating of electrical equipment using thermography

- Checks for looseness of tightening parts or poor contacts in electrical equipment, and heat generation due to thermal deterioration

Losening of the tightning part due to deterioration of the local superheated gasket of the bushing terminal (right side) and the increase in contact resistance led to overheating.

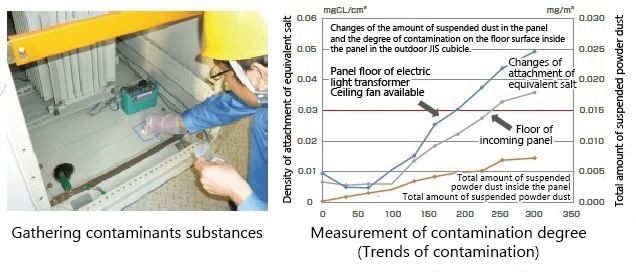

Installation environment diagnosis

We identify environmental stresses that adversely affect electrical equipment and propose appropriate responses and measures before problems occur

- Quantitative evaluation of the degree of fouling by collecting contaminants deposited on electrical room and equipment surfaces

- Analysis of ionic components of collected contaminants to estimate factors that advance corrosion and deterioration

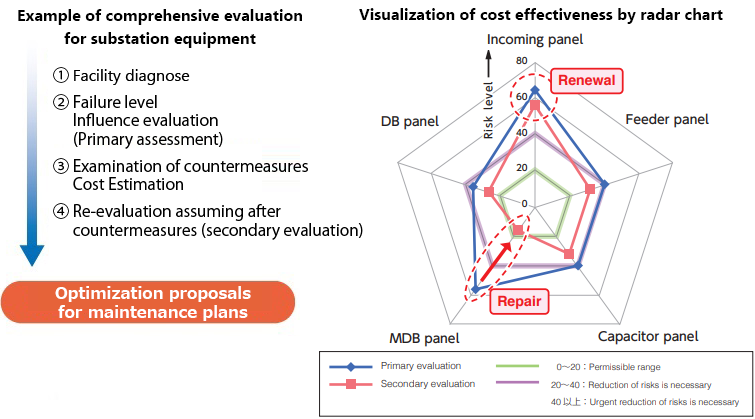

Comprehensive evaluation of electrical eqipment deterioration diagnosis

Provides indicators for maintenance and partial/full renewal of customer facilities

- Comprehensive evaluation by calculating risk levels based on the current level of deterioration of electrical facilities and the impact of failure using MLIT-compliant deterioration evaluation table

Other diagnostic techniques

High-voltage power cable diagnosis (live/deactivated)

- Checks for factors that cause insulation degradation under live wire conditions (measurement of sheath insulation and shielding annealed copper tape resistance)

- *Installation of a dedicated terminal box required

- Checks for insulation deterioration based on detailed diagnosis during equipment shutdown (DC leakage current measurement)

Equipment renewal

Based on the results of equipment diagnosis, we support the formulation of repair, improve reliabilities, and equipment renewal plans based on the customer's facility maintenance plan.

We also support the stability and continuous operation of customers' facilities until equipment renewal.

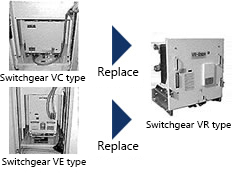

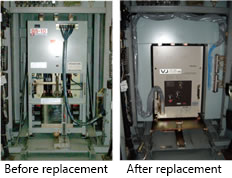

Retrofit / Partial renovation

- Solves the problem of equipment that has exceeded its useful life through partial renovation that makes maximum use of existing equipment.

- Renew of equipment with an alternative that is compatible in electrical function and performance, as well as structurally.

- Innovations to minimize on-site fabrication as much as possible.

- Design and manufacture of substitute equipment in the case none currently exists.

(Support for retrofit type VR )

(Support for retrofit type VJ )

(Support for retrofit type Medimal)